- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Inggris

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Well Casing Couplers, API Sizes, and China’s Manufacturing Leadership

The global energy and construction sectors rely heavily on robust drilling technologies, with well casing coupler systems playing a pivotal role in ensuring structural integrity. As demand grows, casing coupling China manufacturer leaders are driving advancements in precision engineering, aligning their products with standardized API casing sizes to meet international requirements. This article explores the critical interplay between these components, their manufacturing innovations, and the importance of adhering to global standards.

The Role of Well Casing Couplers in Modern Drilling

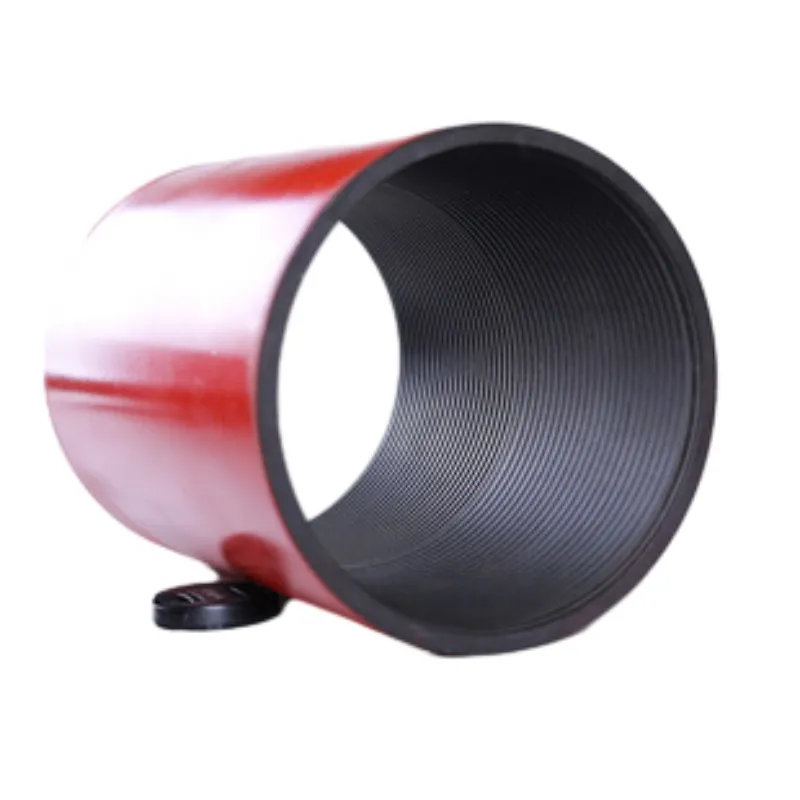

A well casing coupler is a specialized connector designed to join segments of casing pipes, which line boreholes to prevent collapse and contamination. These couplers must withstand extreme pressures, corrosive environments, and mechanical stress. Their design ensures seamlessalignment, enabling efficient extraction of oil, gas, or water.

In drilling operations, even minor leaks or misalignments can lead to catastrophic failures. High-quality couplers mitigate these risks by providing airtight seals and uniform load distribution. Manufacturers now employ advanced alloys and threading techniques to enhance durability, ensuring compatibility with diverse API casing sizes.

Advancements by Casing Coupling China Manufacturers

China has emerged as a global hub for manufacturing precision-engineered casing coupling systems. Leading casing coupling China manufacturer firms leverage automation, AI-driven quality control, and sustainable practices to produce components that meet stringent international standards. By prioritizing R&D, these manufacturers have reduced production costs while improving product longevity.

One notable innovation is the integration of real-time monitoring systems into couplers, enabling operators to detect wear or corrosion early. Additionally, Chinese manufacturers are increasingly adopting eco-friendly processes, such as recycling metal waste and reducing carbon emissions during production.

Understanding API Casing Sizes for Optimal Performance

Standardization is critical in the drilling industry, and API casing sizes provide a universal framework for compatibility. The American Petroleum Institute (API) defines dimensions, weights, and material grades for casing pipes, ensuring interoperability across global projects. Common API sizes range from 4.5 inches to 20 inches in diameter, with varying wall thicknesses for different pressure ratings.

Adhering to API casing sizes allows operators to source components from multiple suppliers without compatibility issues. For casing coupling China manufacturer companies, compliance with API standards is non-negotiable, as it opens doors to international markets. This alignment also simplifies inventory management for drilling firms, reducing downtime caused by mismatched parts.

Future Trends in Well Casing Coupler

The future of well casing coupler systems lies in smart materials and digital integration. Researchers are exploring graphene-coated couplers for enhanced corrosion resistance and self-healing polymers to repair micro-cracks autonomously. Meanwhile, IoT-enabled couplers could transmit real-time data to centralized platforms, optimizing maintenance schedules.

Casing coupling China manufacturer innovators are also experimenting with 3D printing to create custom couplers for unconventional well designs. As renewable energy projects expand, demand for eco-conscious manufacturing processes will grow, pushing manufacturers to adopt greener practices.

Well Casing Coupler FAQs

What is the primary function of a well casing coupler?

A well casing coupler connects casing pipe segments, ensuring structural stability and preventing fluid leakage. It must withstand high pressure and corrosive environments while maintaining alignment with standardized API casing sizes.

How do casing coupling China manufacturers ensure quality?

Leading casing coupling China manufacturer companies use automated production lines, AI-based inspections, and rigorous material testing. Compliance with API casing sizes and international certifications further guarantees reliability.

Why are API casing sizes important in drilling operations?

API casing sizes standardize dimensions and performance metrics, ensuring compatibility across global supply chains. This reduces operational delays and ensures safety in high-pressure environments.

What materials are used in manufacturing well casing couplers?

Most well casing coupler systems are made from carbon steel, stainless steel, or alloy blends. Advanced coatings may be applied to enhance resistance to corrosion and wear.

How do API standards impact casing coupling production?

API standards dictate design specifications, material grades, and testing protocols. Casing coupling China manufacturer producers adhere to these guidelines to meet global client demands and ensure product reliability.

The synergy between well casing coupler technology, casing coupling China manufacturer expertise, and adherence to API casing sizes underscores the drilling industry’s evolution. As innovation accelerates, these components will remain indispensable in achieving safe, efficient, and sustainable resource extraction worldwide.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockWartaNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsWartaNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipWartaNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipWartaNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryWartaNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryWartaNov.03,2025