- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Casing and Tubing Connections in Oil and Gas Applications

Casing and Tubing Connections Understanding the Vital Links in Oil and Gas Production

The oil and gas industry relies heavily on the integrity and performance of casing and tubing connections. These elements serve as critical components in wellbore construction and function, ensuring the safe and efficient extraction of hydrocarbons. With increasing complexity in drilling operations and a growing emphasis on safety and environmental regulations, understanding the nature, design, and maintenance of casing and tubing connections is paramount.

The Importance of Casing and Tubing

Casing and tubing are both types of pipe used in the drilling and production process of oil and gas wells. Casing refers to the large-diameter pipe that is installed in the wellbore to stabilize and protect it from collapse, as well as to isolate various formations and protect groundwater aquifers. Tubing, on the other hand, is the smaller-diameter pipe through which hydrocarbons are produced. These pipes must be connected securely to withstand the high pressures and corrosive environments common in oil and gas wells.

Types of Connections

There are various types of connections used in casing and tubing, each designed to meet specific operational requirements. The primary types include

1. Threaded Connections These involve screw threads that allow for easy assembly and disassembly. They are common in both casing and tubing but require precise manufacturing to ensure a tight seal. Threaded connections can be vulnerable to leakage if not properly maintained.

2. Welded Connections These are created by melting the edges of the pipes and fusing them together. While they provide a strong and permanent bond, they lack the flexibility needed for certain installations and can be more challenging to repair.

3. Coupling Connections Couplings are short pieces of pipe that serve as connectors between two lengths of casing or tubing. They provide relief from the stresses imposed on the joints and can help in making maintenance easier.

4. Premium Connections Designed for high-performance applications, premium connections feature advanced designs that enhance strength, torque resistance, and sealing capabilities. They are often used in high-pressure or high-temperature environments where traditional connections may fail.

Factors Influencing Connection Performance

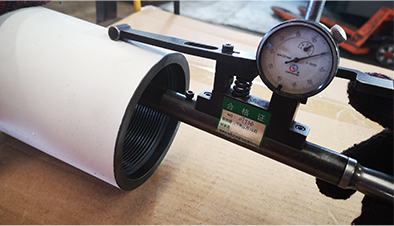

casing and tubing connections

Several factors influence the performance of casing and tubing connections, including

- Material Selection Different materials can affect durability, corrosion resistance, and yield strength. Common materials include carbon steel, alloy steel, and non-ferrous alloys, each suited for specific conditions.

- Environmental Conditions The conditions in which the well operates (such as temperature, pressure, and the presence of corrosive fluids) can dictate the type of connections employed. Connection designs must accommodate these variables to ensure safety and reliability.

- Mechanical Load The connections must withstand various mechanical loads, including internal pressure from fluid and external pressures from the surrounding earth. Proper engineering is essential to prevent failures.

- Installation Techniques The method used to install casing and tubing connections can greatly impact their integrity. Proper training and adherence to industry standards are crucial to achieving optimal results.

Maintenance and Integrity Management

Ensuring the integrity of casing and tubing connections involves ongoing maintenance and monitoring. Regular inspections using advanced methods such as ultrasonic testing and magnetic resonance imaging can help identify potential issues before they lead to catastrophic failures. Additionally, implementing integrity management programs that include performance tracking, risk assessments, and proactive intervention strategies can significantly enhance safety and operational efficiency.

The Future of Casing and Tubing Connections

As the oil and gas industry continues to evolve, so too will the technology and practices surrounding casing and tubing connections. Advances in materials science, digital monitoring, and artificial intelligence are set to revolutionize how connections are designed, installed, and maintained. These innovations promise to enhance the safety, efficiency, and environmental stewardship of oil and gas operations.

Conclusion

Casing and tubing connections play a pivotal role in the success of oil and gas extraction activities. Understanding the different types of connections, the factors affecting their performance, and the importance of maintenance is essential for industry professionals. As technology progresses and the industry faces new challenges, a commitment to innovation and safety in connection technology will be crucial in sustaining the future of oil and gas production. The continuous improvement of these vital links will ensure that the industry can meet the growing global energy demand while minimizing its environmental footprint.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025