- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

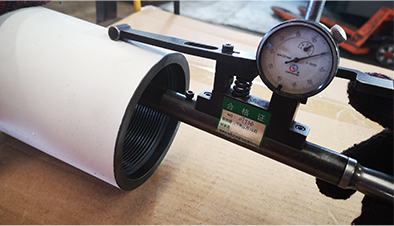

casing pup joint

Understanding Casing Pup Joints Essential Components in Oil and Gas Operations

Casing pup joints are crucial components in the oil and gas industry, serving specific functions that enhance the efficiency and safety of drilling operations. These specialized tubes are designed to connect sections of casing or tubing, providing versatility in length and facilitating operations in various drilling scenarios. This article delves into the significance of casing pup joints, their applications, and the considerations involved in their use.

What is a Casing Pup Joint?

A casing pup joint is a short length of pipe that is used to adjust the lengths of casing strings during the drilling process. Typically ranging from 2 to 30 feet in length, these joints can be custom-manufactured to meet the specific requirements of a drilling operation. Made from high-strength steel or similar materials, casing pup joints have to withstand significant pressure and stress encountered in deep well drilling.

The Importance of Casing Pup Joints

1. Flexibility in Operations Casing pup joints allow drilling engineers to customize the total length of the casing string. This flexibility is crucial for accommodating variations in wellbore depth, which can result from geological changes or drilling conditions. By incorporating pup joints, operations can be optimized to ensure that the casing reaches the desired depth without unnecessary complications.

2. Enhancing Structural Integrity The structural integrity of the wellbore is vital for the safety of drilling operations. Casing pup joints provide an additional layer of reinforcement. When installed correctly, they ensure that the casing maintains its shape and strength, reducing the risk of collapse or deformation under pressure. This is particularly important in high-pressure wells where the integrity of the casing is paramount.

3. Cost-Effectiveness By incorporating casing pup joints into drilling operations, companies can reduce costs associated with over-purchasing of casing material. Rather than using longer lengths of casing, which may lead to excess material and waste, pup joints allow for precise length adjustments, minimizing unnecessary expenses.

Applications and Use Cases

Casing pup joints are used in various scenarios, including

casing pup joint

- Adjusting Casing Lengths One of the primary applications is to adjust the total casing length in a wellbore accurately. This is vital for ensuring that the casing can withstand pressure and perform efficiently under various conditions.

- Isolating Sections of the Wellbore Pup joints can help isolate sections of the wellbore for testing or maintenance. They provide a reliable connection that can be easily accessed when needed.

- Facilitating Workover Programs In workover operations, where existing wells are serviced, pup joints enable quick adjustments to the existing infrastructure, allowing for more efficient maintenance and upgrades.

Considerations for Use

While casing pup joints offer numerous benefits, it is essential to consider certain factors when utilizing them

- Material Selection Choosing the right material is crucial. Casing pup joints must be made from steel that can withstand highly corrosive environments, high pressures, and other adverse conditions found in drilling operations.

- Quality Assurance It’s important to ensure that pup joints meet industry standards to avoid failures that could lead to costly downtime or safety hazards. Regular inspections and testing can help maintain the integrity of the joints.

- Installation Techniques Proper installation is critical. Engineers and technicians must be well-trained in the techniques involved in installing and sealing casing pup joints to prevent leaks and ensure long-term reliability.

Conclusion

Casing pup joints are indispensable tools in the oil and gas industry. Their ability to provide flexibility, enhance structural integrity, and reduce operational costs makes them an essential component in drilling operations. As technology advances and drilling practices evolve, understanding the role of casing pup joints will continue to be crucial for optimizing performance and ensuring safety in an increasingly complex field.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025