- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

petroleum tubing coupling

Understanding Petroleum Tubing Couplings Essential Components in Oil and Gas Operations

In the oil and gas industry, efficient extraction and transportation of hydrocarbons are paramount. Central to these processes are various components designed to withstand the harsh conditions typically encountered in subsurface environments. Among these components, petroleum tubing couplings hold a critical role, enabling the connection of individual lengths of tubing and facilitating the continuous flow of oil and gas from reservoir to surface.

What Are Petroleum Tubing Couplings?

Petroleum tubing couplings are specialized fittings used to join two pieces of tubing. Tubing itself refers to the pipe through which oil and gas are transported from the wellhead to the surface, or in some cases, from one part of a drilling unit to another. Couplings can vary in design, material, and size, but their primary function remains constant to provide a secure, leak-resistant connection under high pressure and challenging conditions.

Types of Petroleum Tubing Couplings

There are several types of couplings used in the petroleum industry, each designed to meet specific application requirements

. The most common types include1. Threaded Couplings These are the traditional type of coupling, characterized by male and female threads that screw together. Threaded couplings are easy to install and remove, making them popular in the industry. However, they may not provide the same level of resistance to high pressures as some other types.

2. Welded Couplings In this type, the ends of the tubing are welded together. This method creates a more robust and pressure-resistant connection, ideal for high-pressure applications. However, welded couplings are less flexible when it comes to future adjustments or repairs, as they necessitate significant cutting and re-welding.

3. Slip-on Couplings These couplings slide over the ends of the pipes being joined. They can be welded in place for a permanent connection or left as a slip joint to allow some movement. Slip-on couplings are often used where alignment of pipes is crucial.

petroleum tubing coupling

4. Flanged Couplings Utilizing a pair of flanges bolted together, flanged couplings are highly versatile and easy to disassemble. They allow for quick maintenance and inspection of the tubing systems.

Choosing the right type of coupling depends on factors such as the pressure and temperature of the fluids being transported, the structural integrity required, and the ease of installation or maintenance.

Materials Used in Coupling Manufacturing

The materials used to manufacture petroleum tubing couplings are critical for their performance. Typically, couplings are made from carbon steel, stainless steel, or specialized alloys that can withstand corrosive environments. The choice of material is influenced by the specific conditions of the oilfield, including temperature, pressure, and the presence of corrosive substances.

Utilizing the proper material can prevent failures that could lead to costly downtime or even hazardous spills. For example, in sour gas environments, where hydrogen sulfide may be present, using corrosion-resistant materials becomes mandatory to ensure long-term integrity.

Importance of Quality Couplings

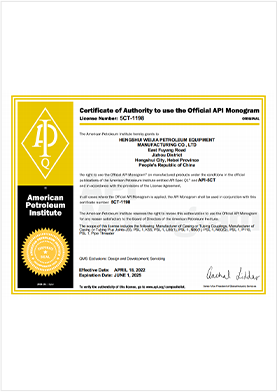

In the oil and gas sector, the integrity of component connections is vital for the safety and efficiency of operations. Faulty couplings can lead to leaks, which not only impact profitability but can also pose significant environmental risks. Therefore, quality control in the manufacturing of petroleum tubing couplings is essential. Adhering to industry standards such as API (American Petroleum Institute) specifications helps ensure that couplings can withstand the demanding conditions of oil and gas extraction.

Conclusion

Petroleum tubing couplings may appear to be simple components, but their importance in the oil and gas industry cannot be underestimated. The effective function of tubing systems relies heavily on these fittings that join lengths of tubings securely. As technologies and techniques in drilling and extraction evolve, the design and materials used in manufacturing couplings will likely continue to advance, enhancing the reliability and efficiency of oil and gas operations worldwide. By understanding the types, materials, and importance of these couplings, industry professionals can make informed decisions that contribute to safer and more productive energy extraction efforts.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025