- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Advanced Techniques in Pipe Manufacturing for Efficient Production Processes

The Pipe Mill A Pillar of Modern Industry

In the contemporary landscape of manufacturing, the pipe mill stands as a critical facility dedicated to the production of pipes used across various sectors including oil and gas, construction, and water distribution. With the increasing demand for robust and durable piping solutions, the pipe mill has evolved into a sophisticated establishment, harnessing advanced technologies for efficiency and quality control.

The Evolution of Pipe Mills

Historically, pipe fabrication was a labor-intensive process, predominantly reliant on manual efforts. The industrial revolution ushered in mechanical innovations, allowing for the mass production of pipes. The 20th century saw the transformation of pipe manufacturing into a highly automated and specialized sector. Modern pipe mills utilize electric resistance welding (ERW) and submerged arc welding (SAW) processes to produce seamless and welded pipes. These advancements not only enhance production speed but also improve the structural integrity of the pipes, making them suitable for a wider range of applications.

Key Processes in Pipe Manufacturing

A typical pipe mill facility encompasses several key processes that transform raw materials into finished products. The journey begins with the selection of high-quality steel billets or coils, which are melted and shaped into one of several configurations, such as round, square, or rectangular sections. Depending on the specifications, these materials undergo processes such as hot rolling, cold forming, and welding.

1. Hot Rolling In this initial stage, the heated steel is passed through rollers to achieve the desired shape and thickness. Hot rolling is essential for producing large diameter pipes and helps in enhancing the material’s mechanical properties.

2. Cold Forming Cold forming is employed to enhance the dimensional accuracy and surface finish of the pipes. The process occurs at room temperature, which increases the yield strength of the material and reduces the likelihood of defects.

pipe mill

3. Welding Once the pipe is formed, welding is employed to join the edges or seams. In ERW, electrical resistance is used to heat and bond the edges, while SAW utilizes a submerged arc to produce a strong, continuous weld bead. Both methods ensure that the pipe meets stringent industry standards for quality and reliability.

4. Finishing After welding, pipes undergo several finishing processes, including heat treatment, surface treatment (such as coating or galvanization), and quality inspection. This stage is critical in ensuring that the pipes can withstand the harsh conditions of their end use, particularly in industries like oil and gas where corrosion resistance is paramount.

The Role of Technology in Pipe Mills

In recent years, the integration of technology in pipe mills has revolutionized production methods. Automation and robotics play a significant role in enhancing efficiency, reducing labor costs, and improving precision. Moreover, the implementation of Industry 4.0 concepts, such as the Internet of Things (IoT) and data analytics, allows for real-time monitoring of machinery and processes, facilitating predictive maintenance and optimizing production schedules.

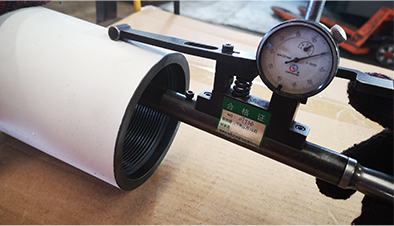

Quality control remains a top priority in pipe manufacturing. Advanced non-destructive testing methods, such as ultrasonic testing and X-ray inspection, are employed to ensure that the pipes meet various international standards. These practices not only guarantee the safety and reliability of the pipes but also foster trust among customers and industries that utilize these essential components.

Conclusion

The pipe mill represents a vital component of modern infrastructure, providing essential materials needed for a wide range of applications. As industries continue to evolve and expand, the importance of innovative and efficient pipe manufacturing processes cannot be overstated. By embracing new technologies and adhering to stringent quality controls, pipe mills are well-positioned to meet the demands of the future and contribute to the overall growth of the global economy. Whether in transporting water, oil, or gases, the significance of high-quality pipes produced in today’s pipe mills remains indispensable.

-

Tubing coupling plays a significant role in the chemical industryNewsApr.03,2025

-

The Importance of Tubing Crossover in Various Industrial FieldsNewsApr.03,2025

-

The characteristics and important role of Tubing Pup JointNewsApr.03,2025

-

Characteristics and functions of Pup jointNewsApr.03,2025

-

Characteristics and Functions of Pup Joint PipeNewsApr.03,2025

-

Application of Coupling Casing in Various ScenariosNewsApr.03,2025