- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

pup joint specifications

Understanding PUP Joint Specifications A Comprehensive Guide

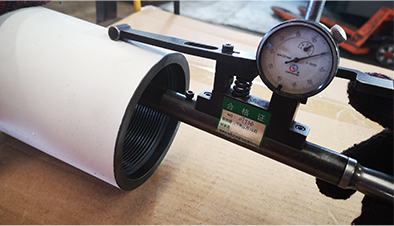

The mechanical and engineering industries demand high standards for components to ensure safety, efficiency, and reliability. One such crucial component is the PUP (Pick-Up-Pull) joint, widely utilized in various applications, including piping systems and structural frameworks. This article explores the specifications and importance of PUP joints in engineering design and manufacturing.

What Are PUP Joints?

PUP joints, or Pick-Up-Pull joints, are specialized connectors that facilitate the joining of two or more segments of pipes or structural elements. They are designed to provide a robust connection while allowing for some movement, which is essential in dynamic environments. These joints are particularly valuable in systems that experience thermal expansion, vibration, or other stresses that could lead to misalignment or failure if rigidly connected.

Key Specifications of PUP Joints

1. Material Composition PUP joints can be made from various materials, including steel, stainless steel, and composite materials. The choice of material largely depends on the application, environmental conditions, and the specific requirements of the project. For instance, stainless steel is often preferred for corrosive environments due to its resistance to oxidation and rust.

2. Diameter and Size The diameter of PUP joints must match the pipes or structural elements they are intended to connect. Generally, they come in a range of sizes to accommodate different pipe diameters, ensuring a secure fit. Accurate measurements are essential for preventing leaks and maintaining the integrity of the system.

3. Pressure Rating It’s crucial to identify the pressure rating of a PUP joint before its application. This rating indicates the maximum internal pressure that the joint can withstand without failure. Applications involving high-pressure systems require joints with a higher pressure rating to ensure safety and functionality.

4. Temperature Resistance PUP joints should also be evaluated for their temperature tolerance. The materials used in manufacturing these joints must be selected based on the expected temperature range of the application. High-temperature applications may require heat-resistant materials that can maintain mechanical properties under stress.

5. Design Features Often, PUP joints include additional design features to enhance performance, such as locking mechanisms, gaskets for sealing, and optional reinforcements. These features help prevent leakage and improve the joint's overall integrity.

pup joint specifications

6. Installation Requirements Proper installation is crucial for the performance of PUP joints. Specifications typically include guidelines for alignment, torque requirements, and the need for sealing compounds or gaskets. Adhering to these specifications during installation can significantly reduce the risk of future issues.

7. Testing and Certification Many PUP joints undergo rigorous testing to ensure they meet industry standards. Common testing protocols include pressure testing, leak testing, and material compliance checks. Receiving certification from relevant authorities can enhance the credibility of the joints and assure users of their quality.

Importance of PUP Joint Specifications

Understanding and adhering to PUP joint specifications is vital for several reasons

- Safety Ensuring that PUP joints meet the required specifications minimizes the risk of failure, which can lead to catastrophic accidents, especially in high-pressure industrial settings.

- Efficiency Properly selected and installed PUP joints contribute to the overall efficiency of the system. They minimize energy losses and prevent leaks, thereby reducing operational costs.

- Longevity PUP joints built from high-quality materials and designed according to specifications have a longer lifespan, reducing the frequency of repairs or replacements and, ultimately, saving costs.

Conclusion

PUP joint specifications play a pivotal role in the successful implementation of mechanical and structural systems. By understanding and applying the right specifications, engineers and designers can enhance the safety, efficiency, and reliability of their projects. As industries continue to evolve, the importance of quality manufacturing and precise specifications for components like PUP joints will undoubtedly remain paramount. Proper attention to these details ensures that systems operate smoothly and safely, ultimately contributing to the advancement of engineering practices.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025