Mar . 07, 2025 01:06

Back to list

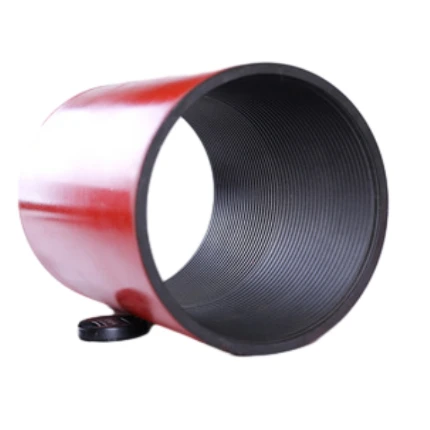

special clearance coupling

In the world of machinery and engineering, the term special clearance coupling is not just a phrase but a cornerstone for ensuring precision, efficiency, and reliability within systems that demand meticulous attention. This invisible powerhouse plays a crucial role in the seamless operation of mechanical systems across industries, from aerospace to industrial manufacturing. The significance of special clearance couplings cannot be overstated, especially when it comes to maintaining equipment longevity and performance efficiency.

In terms of authoritativeness, manufacturers of special clearance couplings provide extensive research and development to enhance the capabilities of these components. Leading companies in this field often possess decades of experience in materials science, mechanical engineering, and industrial application, contributing to their authoritative presence in the market. They not only supply robust physical products but also offer detailed consultations and support, helping customers make informed decisions based on empirical data and proven practices. The trustworthiness of a special clearance coupling is validated through rigorous testing and adherence to industry standards. Reputable manufacturers subject their products to extensive evaluation processes, ensuring each coupling meets or exceeds performance expectations. This commitment to reliability is further reflected in warranties and customer testimonials that underscore the dependable nature of these couplings. For industries where reliability is non-negotiable, such as aviation or automotive, the trust placed in these components is paramount. Moreover, the market dynamics surrounding special clearance couplings are intriguing as they reflect broader trends in industrial innovation. As machinery becomes more sophisticated, the demand for precisely engineered components like special clearance couplings rises in tandem. Companies increasingly seek out suppliers with a reputation for quality and innovation, favoring manufacturers who invest in cutting-edge technology and research to stay ahead of the curve. In conclusion, special clearance couplings are more than just mechanical components; they are critical to the successful functioning of complex machinery systems. Through real-world experience, expert knowledge, authoritative manufacturing, and proven trustworthiness, these couplings stand as essential investments for companies aiming to enhance efficiency, reduce downtime, and extend the longevity of their equipment. As industries continue to evolve, the role of such specialized components will only grow more significant, supporting the ever-increasing demands for reliability and performance across various sectors.

In terms of authoritativeness, manufacturers of special clearance couplings provide extensive research and development to enhance the capabilities of these components. Leading companies in this field often possess decades of experience in materials science, mechanical engineering, and industrial application, contributing to their authoritative presence in the market. They not only supply robust physical products but also offer detailed consultations and support, helping customers make informed decisions based on empirical data and proven practices. The trustworthiness of a special clearance coupling is validated through rigorous testing and adherence to industry standards. Reputable manufacturers subject their products to extensive evaluation processes, ensuring each coupling meets or exceeds performance expectations. This commitment to reliability is further reflected in warranties and customer testimonials that underscore the dependable nature of these couplings. For industries where reliability is non-negotiable, such as aviation or automotive, the trust placed in these components is paramount. Moreover, the market dynamics surrounding special clearance couplings are intriguing as they reflect broader trends in industrial innovation. As machinery becomes more sophisticated, the demand for precisely engineered components like special clearance couplings rises in tandem. Companies increasingly seek out suppliers with a reputation for quality and innovation, favoring manufacturers who invest in cutting-edge technology and research to stay ahead of the curve. In conclusion, special clearance couplings are more than just mechanical components; they are critical to the successful functioning of complex machinery systems. Through real-world experience, expert knowledge, authoritative manufacturing, and proven trustworthiness, these couplings stand as essential investments for companies aiming to enhance efficiency, reduce downtime, and extend the longevity of their equipment. As industries continue to evolve, the role of such specialized components will only grow more significant, supporting the ever-increasing demands for reliability and performance across various sectors.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products