- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

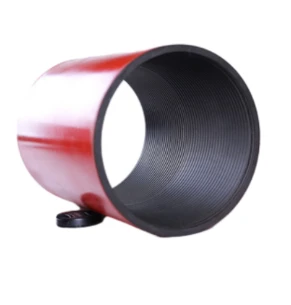

stainless pipe coupling

Understanding Stainless Steel Pipe Couplings A Comprehensive Overview

Stainless steel pipe couplings are essential components in piping systems that serve the critical function of connecting two sections of pipe. As industries worldwide continue to expand and evolve, the demand for durable, reliable, and corrosion-resistant materials has led to the widespread adoption of stainless steel in various applications, ranging from plumbing to industrial processes.

What is a Stainless Steel Pipe Coupling?

A stainless steel pipe coupling is a short piece of pipe with male threads on both ends, designed to connect two pipes together. Couplings can also come in forms such as weld-on or slip-on, depending on the requirements of the piping system. The primary purpose of a coupling is to provide an effective transition between different sections of piping, allowing for continuity in flow and pressure.

Types of Stainless Steel Pipe Couplings

1. Threaded Couplings These are perhaps the most common type of stainless steel couplings that feature internal threads. They are easy to install, as they can be simply screwed onto the pipes.

2. Welded Couplings These couplings are designed for more permanent connections. They are welded onto the pipes, creating a strong bond that can withstand high pressures and temperatures.

3. Slip-on Couplings As the name suggests, these couplings slide over the ends of the pipes and are then welded in place. They are often used in applications where a flush finish is essential.

4. Reducing Couplings These couplings allow the connection of pipes of different diameters. They are crucial in systems where the flow must be adapted to suit varying pipe sizes.

5. Clamp Couplings These can be used for quick repairs or temporary connections. They feature a metal clamp that secures the pipe ends together, providing ease of installation and flexibility.

Advantages of Stainless Steel Couplings

Stainless steel is favored over other materials for a variety of reasons

1. Corrosion Resistance Stainless steel is known for its ability to withstand rust and oxidation, making it ideal for applications in harsh environments, such as chemical processing plants and marine settings.

2. Durability and Strength Stainless steel is incredibly strong and can handle high pressures and temperatures, contributing to the longevity of the piping system.

stainless pipe coupling

3. Aesthetic Appeal The clean, shiny look of stainless steel not only performs well but also maintains a modern appearance, making it suitable for architectural applications.

Applications of Stainless Steel Pipe Couplings

Stainless steel pipe couplings are widely applied across various industries, including

- Plumbing For connecting domestic water supply lines. - Oil and Gas In drilling and refining processes, where high-pressure and corrosion-resistant materials are necessary. - Food and Beverage In breweries and food processing plants, where hygiene and cleanliness are critical. - Pharmaceuticals For sterile systems that prevent contamination. - Chemical Processing Where aggressive chemicals are present, and corrosion resistance is essential.

Selection Criteria for Stainless Steel Couplings

When choosing the right stainless steel pipe coupling, several factors need to be considered

1. Type of Connection Determine whether a threaded, welded, or other type of coupling is most appropriate for your system.

2. Pipe Material and Size Ensure the coupling is compatible with the type of stainless steel and size of the pipes you are using.

3. Pressure and Temperature Ratings Match the coupling’s specifications with the operational requirements of your piping system.

4. Corrosion Resistance Consider the environment in which the coupling will be used and select the appropriate grade of stainless steel (e.g., 304, 316) based on exposure to corrosive elements.

5. Cost While stainless steel couplings generally deliver high performance, it is essential to balance quality with budgetary constraints.

Conclusion

In conclusion, stainless steel pipe couplings are integral to modern piping systems, offering a blend of strength, durability, and resistance to corrosion. Their diverse applications across numerous industries highlight their importance in maintaining the integrity and efficiency of fluid transportation systems. When selecting a coupling, considerations like connection type, compatibility, and environmental factors are necessary to ensure the best performance and longevity. As industries continue to develop, the role of stainless steel pipe couplings will only grow, underscoring their value in engineering and infrastructure projects.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025