- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

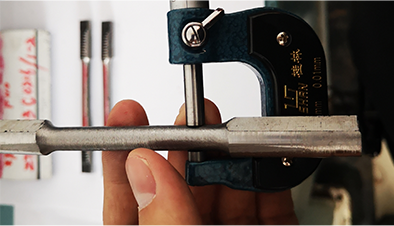

steel coupling

Understanding Steel Couplings A Comprehensive Overview

Steel couplings are essential components in various mechanical systems, playing a crucial role in transmitting motion and torque between shafts. They are widely used in industries ranging from manufacturing to transportation, ensuring efficient and reliable connections. This article delves into the significance of steel couplings, their types, applications, and advantages, providing a comprehensive understanding of their role in engineering and industrial sectors.

What are Steel Couplings?

Steel couplings are mechanical devices designed to connect two shafts together while allowing for a certain degree of misalignment, axial movement, or angular displacement. These couplings are typically made from high-strength steel, which offers durability and resistance to wear and corrosion. The primary function of a steel coupling is to transfer power from one shaft to another while minimizing the risk of mechanical failure.

Types of Steel Couplings

There are several types of steel couplings available, each designed for specific applications and operational conditions. Here are a few common types

1. Rigid Couplings These couplings provide a solid and inflexible connection between two shafts, ensuring precise alignment. They are ideal for applications where misalignment is minimal and high torque transmission is required.

2. Flexible Couplings Unlike rigid couplings, flexible couplings can accommodate misalignment between shafts, which is essential in applications with vibration or thermal expansion. They provide shock absorption and reduce mechanical stress on the connected components.

3. Universal Joint Couplings These couplings can accommodate angular misalignment and are often used in applications where shafts are not in a straight line. They are commonly found in automotive drive shafts and various machinery.

4. Oldham Couplings Oldham couplings consist of three parts two hubs and a center disc. This design allows for angular and parallel misalignment, making them suitable for applications where precise movement is vital, such as in robotics.

Applications of Steel Couplings

Steel couplings find applications in diverse fields

steel coupling

- Industrial Machinery In factories, steel couplings are often used in motors, pumps, and conveyors to facilitate power transmission between components.

- Automotive In vehicles, they connect various drive shafts and axles, ensuring smooth operation and efficient power transfer.

- Aerospace In the aerospace industry, steel couplings are critical in connecting control surfaces and drive systems, ensuring reliable performance under extreme conditions.

- Construction Equipment Heavy machinery such as cranes and excavators relies on steel couplings for power transmission between engines and operational components.

Advantages of Steel Couplings

Steel couplings offer numerous advantages that make them a preferred choice in many applications

1. Strength and Durability Made from high-quality steel, these couplings exhibit excellent tensile strength and resistance to wear, making them suitable for heavy-duty applications.

2. Versatility With various types available, steel couplings can be used in a wide range of industrial applications, accommodating different operational requirements.

3. Reduced Maintenance Steel couplings require minimal maintenance compared to other coupling materials, which can lead to lower operational costs over time.

4. High Torque Capacity Steel couplings are capable of transmitting significant torque levels, making them ideal for demanding industrial applications.

Conclusion

In summary, steel couplings play a vital role in connecting shafts and transmitting power in various mechanical systems across a wide range of industries. Their strength, durability, and versatility make them an indispensable component in engineering applications. Understanding the different types of steel couplings and their specific uses is essential for engineers and industry professionals aiming to optimize mechanical performance and ensure the longevity of their equipment. As technology advances, the design and application of steel couplings will continue to evolve, enhancing their efficiency and reliability in an ever-changing industrial landscape.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025