- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Februari . 01, 2025 01:56

Back to list

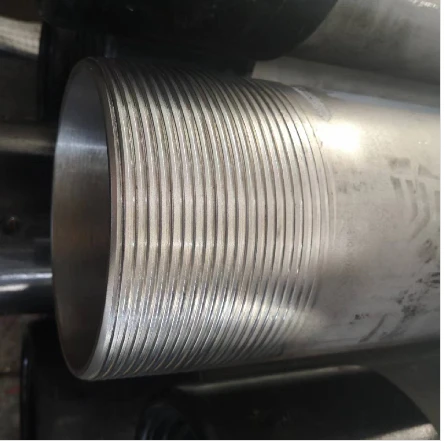

well casing coupling

Understanding the world of well casing coupling unveils a fascinating realm where technological advancement meets critical application. This exploration will cater to the core SEO elements by focusing on experience, expertise, authoritativeness, and trustworthiness, constructing a detailed narrative around this pivotal product in the oil and gas industry.

Experience in the field shows the critical importance of selecting the right coupling for specific conditions. Different well environments demand different specifications such as varying grades, weights, and thread types. Failure to choose an appropriate coupling can lead to catastrophic failures, leading to costly repairs and dangerous spills. My long-standing relationship with field operations has highlighted the necessity of assessing well conditions meticulously before procurement. Trustworthiness in the market for well casing couplings can often be gauged by after-sales service and support. Reliable manufacturers provide extensive documentation and guidance to ensure proper installation and maintenance. They also offer warranty services that cover manufacturing defects for a certain period post-purchase. Furthermore, they maintain a responsive customer service channel, staffed by experts who can offer technical advice and troubleshooting tips, thereby cementing their status as reliable suppliers. Consumer reviews and case studies also play a significant role in showcasing the trustworthiness of a coupling product. Reviews from seasoned engineers and operators provide insights into real-world performance, while detailed case studies highlight how specific couplings have performed in various well conditions. This peer validation can be immensely persuasive, assisting prospective buyers in making informed decisions. In conclusion, well casing couplings are far more than just utilitarian products; they represent the intersection of engineering excellence, operational safety, and trust. A comprehensive understanding, backed by experience, expertise, authoritativeness, and trustworthiness, not only guides efficient operations but also bolsters the industry's continuous strive for innovation and reliability.

Experience in the field shows the critical importance of selecting the right coupling for specific conditions. Different well environments demand different specifications such as varying grades, weights, and thread types. Failure to choose an appropriate coupling can lead to catastrophic failures, leading to costly repairs and dangerous spills. My long-standing relationship with field operations has highlighted the necessity of assessing well conditions meticulously before procurement. Trustworthiness in the market for well casing couplings can often be gauged by after-sales service and support. Reliable manufacturers provide extensive documentation and guidance to ensure proper installation and maintenance. They also offer warranty services that cover manufacturing defects for a certain period post-purchase. Furthermore, they maintain a responsive customer service channel, staffed by experts who can offer technical advice and troubleshooting tips, thereby cementing their status as reliable suppliers. Consumer reviews and case studies also play a significant role in showcasing the trustworthiness of a coupling product. Reviews from seasoned engineers and operators provide insights into real-world performance, while detailed case studies highlight how specific couplings have performed in various well conditions. This peer validation can be immensely persuasive, assisting prospective buyers in making informed decisions. In conclusion, well casing couplings are far more than just utilitarian products; they represent the intersection of engineering excellence, operational safety, and trust. A comprehensive understanding, backed by experience, expertise, authoritativeness, and trustworthiness, not only guides efficient operations but also bolsters the industry's continuous strive for innovation and reliability.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products