Feb . 16, 2025 16:21

Back to list

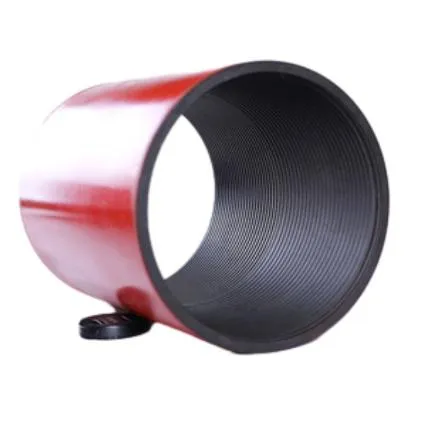

what is a bull plug used for

Bull plugs are integral components in various industrial and construction fields across the globe, yet they remain a subject of curiosity for many. Their purposeful design adapts to high-stress environments in industries such as plumbing, oil drilling, and gas extraction, marking them as an essential asset among other tools and components.

Exploring further into water management, bull plugs are utilized in pipeline systems within residential and commercial plumbing. They safely cap pipes that are not currently in use, preventing leaks, conserving water, and maintaining system pressure. This enhances the overall efficiency and longevity of the plumbing system, underlining the broad usability across various industries. Trustworthiness in the use and application of bull plugs is established through consistent adherence to industry standards and guidelines. Manufacturers and suppliers undergo rigorous testing and quality assurance processes to certify their bull plugs under industry-specific regulatory bodies. This certification process often involves testing for pressure resistance, material strength, and durability, ensuring that only those meeting stringent standards are deployed in critical applications. Recently, advancements in materials science have introduced new alloy composites for bull plugs that offer even greater resistance to corrosion and stress, extending their life expectancy and reliability further. These innovations, backed by authoritative research in industrial engineering, promise enhancements in pipeline safety and efficiency and affirm the future of bull plugs as indispensable components in modern industrial applications. For professionals aiming to purchase or utilize bull plugs, engaging with reputable manufacturers and suppliers is of paramount importance. Their expertise can offer guidance tailored to specific project needs, ensuring the selection of the appropriate type and material that adheres to the necessary safety standards. Through continued education and adaptation to technological advancements, maintaining the authority and trustworthiness that defines this product's use will ensure its effective deployment and performance. In thought leadership discussions, consensus frequently highlights bull plugs as exemplar components in sustainable industrial practices. Their effective application not only enhances operational safety but also protects environmental surroundings from potential hazards due to leaks. As such, mastering the application of bull plugs remains a critical skill for industry professionals worldwide, reflecting their significant role and reliability in sustainable resource management.

Exploring further into water management, bull plugs are utilized in pipeline systems within residential and commercial plumbing. They safely cap pipes that are not currently in use, preventing leaks, conserving water, and maintaining system pressure. This enhances the overall efficiency and longevity of the plumbing system, underlining the broad usability across various industries. Trustworthiness in the use and application of bull plugs is established through consistent adherence to industry standards and guidelines. Manufacturers and suppliers undergo rigorous testing and quality assurance processes to certify their bull plugs under industry-specific regulatory bodies. This certification process often involves testing for pressure resistance, material strength, and durability, ensuring that only those meeting stringent standards are deployed in critical applications. Recently, advancements in materials science have introduced new alloy composites for bull plugs that offer even greater resistance to corrosion and stress, extending their life expectancy and reliability further. These innovations, backed by authoritative research in industrial engineering, promise enhancements in pipeline safety and efficiency and affirm the future of bull plugs as indispensable components in modern industrial applications. For professionals aiming to purchase or utilize bull plugs, engaging with reputable manufacturers and suppliers is of paramount importance. Their expertise can offer guidance tailored to specific project needs, ensuring the selection of the appropriate type and material that adheres to the necessary safety standards. Through continued education and adaptation to technological advancements, maintaining the authority and trustworthiness that defines this product's use will ensure its effective deployment and performance. In thought leadership discussions, consensus frequently highlights bull plugs as exemplar components in sustainable industrial practices. Their effective application not only enhances operational safety but also protects environmental surroundings from potential hazards due to leaks. As such, mastering the application of bull plugs remains a critical skill for industry professionals worldwide, reflecting their significant role and reliability in sustainable resource management.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products