- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- ஆங்கிலம்

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

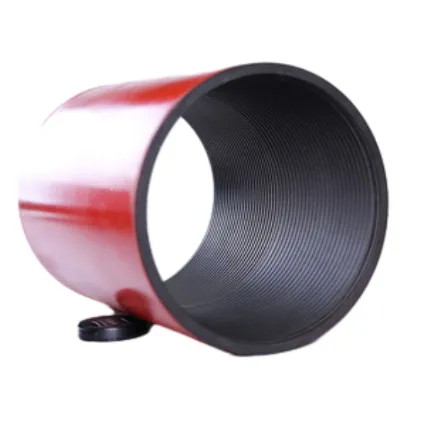

Right Casing Couplings for Your Project

When it comes to drilling operations, selecting the correct casing coupling is vital to ensure the success, safety, and longevity of the well. Whether you're working with a wholesale L80 casing coupling, China finished casing coupling, or a well casing coupler, choosing the right type of coupling based on your project requirements can make a significant difference in overall performance. The key factors to consider include size, material, and threading type. These elements directly affect the durability, strength, and sealing capabilities of the casing string. Let’s explore how to make the right selection for your project needs.

Size of the Casing Coupling: Matching the Casing Diameter and Project Specifications

The size of the casing coupling is one of the most crucial factors in selecting the right coupling for your project. The coupling must match the diameter of the casing pipe to create a secure and stable connection. For example, if you're working with a 6-inch casing coupling or a larger L80 casing coupling, it's essential that the coupling fits the casing pipe precisely to avoid leaks or failure during operation.

When selecting the right size, make sure to consider the specific requirements of your drilling operation. உறை இணைப்புகள் come in various sizes, and choosing the wrong size can lead to poor connection integrity, resulting in inefficient drilling, increased downtime, or even dangerous pressure losses. The correct sizing ensures that the casing string remains sealed, which is critical for fluid flow management and pressure containment.

Material of Casing Couplings: Durability and Resistance to Harsh Conditions

The material of the casing coupling plays a vital role in determining its ability to withstand the harsh conditions of drilling operations. Depending on the environment and the type of resources being extracted, different materials are required to provide the necessary strength, corrosion resistance, and durability. Common materials for well casing couplers include carbon steel, stainless steel, and alloy steel.

For example, China finished casing couplings are often made of high-quality steel or specialized alloys to resist corrosion and wear, especially in offshore or deep-water drilling operations. If you're dealing with aggressive fluids or high-temperature environments, material selection becomes even more critical. For operations in harsh or extreme environments, selecting a corrosion-resistant material like stainless steel or alloy steel is highly recommended.

Threading Type of Casing Couplings: Ensuring Proper Connection and Sealing

The threading type is another important factor in choosing the right casing coupling. The threading ensures that the casing pipes and couplings connect securely, allowing the casing to maintain integrity and prevent fluid leakage. Several threading options are available, with API threads being among the most widely used in the industry.

For L80 casing couplings, API threads are often employed to ensure reliable and secure connections. These threads are designed to provide a high level of sealing, which is essential for managing pressure and preventing contamination. It's important to check that the threading type of your casing coupling matches that of the casing pipe to avoid issues with alignment or sealing.

Additionally, some couplings may have buttress threads, which are designed to withstand higher loads and are commonly used in deeper or high-pressure wells. Selecting the right thread type ensures a strong, secure connection that can handle the stresses and pressures of the drilling environment.

In conclusion, selecting the appropriate casing coupling, such as the wholesale L80 casing coupling, China finished casing coupling, or well casing coupler, is essential for the safety and efficiency of any drilling operation. When making your selection, always consider the size, material, and threading type to ensure that the coupling meets the specific requirements of your project. Properly chosen couplings will not only enhance the performance of the well but also improve its longevity, reducing the risk of failure and increasing overall operational efficiency.

-

Tubing Crossover - API Compatible, Custom Sizes, In Stockசெய்திNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel Couplingsசெய்திNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast Shipசெய்திNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick Shipசெய்திNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast Deliveryசெய்திNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast Deliveryசெய்திNov.03,2025