- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

జూన్ . 17, 2024 10:56

Back to list

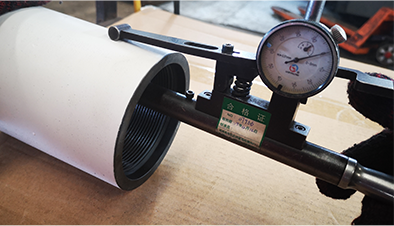

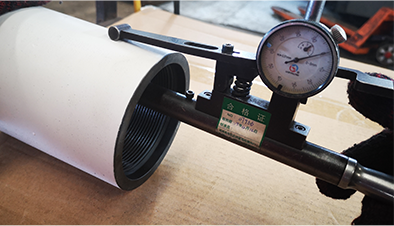

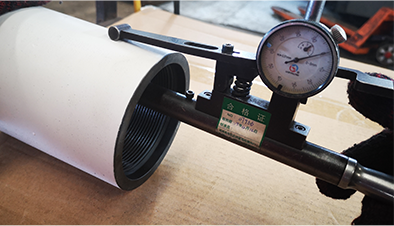

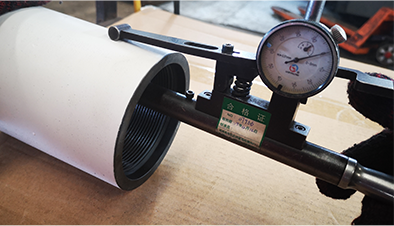

Stainless steel reducer coupling

Stainless Steel Reducer Couplings A Comprehensive Guide

Reducer couplings are essential components in fluid power systems, connecting two shafts with different diameters. They play a crucial role in transmitting torque and ensuring smooth operation of the system. Among various materials used for reducer couplings, stainless steel is particularly popular due to its excellent corrosion resistance, strength, and durability.

Stainless steel reducer couplings are typically made from 304 or 316 stainless steel, which are known for their high levels of corrosion resistance and strength. These materials are also easy to machine and form, making it possible to create precise and reliable couplings that meet specific application requirements.

One of the key advantages of stainless steel reducer couplings is their ability to withstand harsh operating conditions. Whether you're working in a chemical processing plant, food and beverage industry, or any other environment where exposure to corrosive substances is likely, these couplings can provide long-lasting performance without requiring frequent maintenance or replacement.

Another important consideration when selecting stainless steel reducer couplings is their size and configuration. Couplings are available in a wide range of sizes and configurations to suit different applications. It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment

It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment stainless steel reducer coupling.

When it comes to installation and maintenance, stainless steel reducer couplings are relatively straightforward. Proper installation is critical to ensure optimal performance and longevity of the coupling. This typically involves aligning the shafts accurately and tightening the coupling securely using the appropriate tools and fasteners. Regular maintenance, such as cleaning and lubrication, can help prevent premature wear and extend the life of the coupling.

In conclusion, stainless steel reducer couplings are an excellent choice for a wide range of fluid power applications. Their corrosion resistance, strength, and durability make them well-suited for harsh operating conditions, while their versatility and ease of use make them a popular choice among engineers and technicians. By carefully selecting the right size and configuration, and following proper installation and maintenance guidelines, you can enjoy reliable performance and long service life from your stainless steel reducer couplings.

stainless steel reducer coupling.

When it comes to installation and maintenance, stainless steel reducer couplings are relatively straightforward. Proper installation is critical to ensure optimal performance and longevity of the coupling. This typically involves aligning the shafts accurately and tightening the coupling securely using the appropriate tools and fasteners. Regular maintenance, such as cleaning and lubrication, can help prevent premature wear and extend the life of the coupling.

In conclusion, stainless steel reducer couplings are an excellent choice for a wide range of fluid power applications. Their corrosion resistance, strength, and durability make them well-suited for harsh operating conditions, while their versatility and ease of use make them a popular choice among engineers and technicians. By carefully selecting the right size and configuration, and following proper installation and maintenance guidelines, you can enjoy reliable performance and long service life from your stainless steel reducer couplings.

It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment

It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment It's important to choose a coupling that provides the necessary torque capacity and flexibility to accommodate variations in shaft alignment and misalignment stainless steel reducer coupling.

When it comes to installation and maintenance, stainless steel reducer couplings are relatively straightforward. Proper installation is critical to ensure optimal performance and longevity of the coupling. This typically involves aligning the shafts accurately and tightening the coupling securely using the appropriate tools and fasteners. Regular maintenance, such as cleaning and lubrication, can help prevent premature wear and extend the life of the coupling.

In conclusion, stainless steel reducer couplings are an excellent choice for a wide range of fluid power applications. Their corrosion resistance, strength, and durability make them well-suited for harsh operating conditions, while their versatility and ease of use make them a popular choice among engineers and technicians. By carefully selecting the right size and configuration, and following proper installation and maintenance guidelines, you can enjoy reliable performance and long service life from your stainless steel reducer couplings.

stainless steel reducer coupling.

When it comes to installation and maintenance, stainless steel reducer couplings are relatively straightforward. Proper installation is critical to ensure optimal performance and longevity of the coupling. This typically involves aligning the shafts accurately and tightening the coupling securely using the appropriate tools and fasteners. Regular maintenance, such as cleaning and lubrication, can help prevent premature wear and extend the life of the coupling.

In conclusion, stainless steel reducer couplings are an excellent choice for a wide range of fluid power applications. Their corrosion resistance, strength, and durability make them well-suited for harsh operating conditions, while their versatility and ease of use make them a popular choice among engineers and technicians. By carefully selecting the right size and configuration, and following proper installation and maintenance guidelines, you can enjoy reliable performance and long service life from your stainless steel reducer couplings. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products