- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 12, 2025 17:33

Back to list

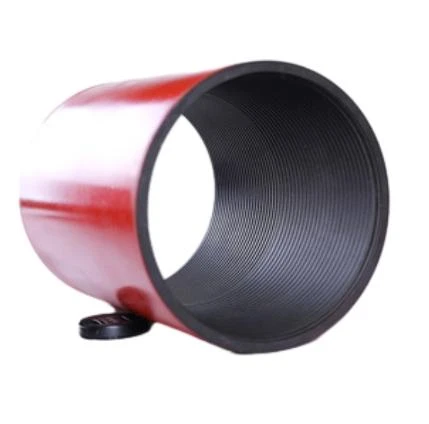

1 4 inch tube coupling

Choosing the right 1/4 inch tube coupling is crucial for anyone looking to ensure seamless connections in their piping systems. With industries ranging from automotive to healthcare relying heavily on these little components, it's essential to understand why they matter and how to select the best among the plethora of options available.

Seek out manufacturers who adhere to industry standards and certifications like ISO or ANSI. These certifications are not merely bureaucratic stamps but serve as assurance of quality, manufacturing standards, and safety. Compliance with these standards signifies that the coupling can be reliably used in specific environments, especially those with stringent safety and performance requirements. Installation and Maintenance Keeping it Simple Ease of installation is another critical aspect when choosing tube couplings. A well-designed coupling should facilitate straightforward installation processes, reducing time and labor costs. Furthermore, regular maintenance checks should be manageable. Couplings that incorporate features such as self-sealing technologies can provide further simplification by eliminating the need for sealing tape or additional welds, thus reducing maintenance efforts over time. The Digital Advantage Embracing Technology Many companies now offer digital interfaces that assist in the selection and ordering processes. These platforms often provide comprehensive data, including CAD models, pressure ratings, and material compatibility charts. Embracing these digital assets not only simplifies the purchasing process but also aids in ensuring that the right product is chosen for the specific application. Conclusion Making an Informed Decision In the age of rapid technological advancement and increased specialization, choosing the right 1/4 inch tube coupling is more than just a matter of specification matching. It is about understanding the application requirements, material compatibility, and installation considerations, all while ensuring compliance with industry standards. Invest time in selecting a reputable supplier and accessing expert advice, which can be pivotal in making an informed decision. After all, these small but mighty components play a critical role in the efficiency and reliability of entire systems. By adopting a strategic approach to selecting tube couplings, businesses can enhance performance, reduce maintenance costs, and ensure longevity in their operations.

Seek out manufacturers who adhere to industry standards and certifications like ISO or ANSI. These certifications are not merely bureaucratic stamps but serve as assurance of quality, manufacturing standards, and safety. Compliance with these standards signifies that the coupling can be reliably used in specific environments, especially those with stringent safety and performance requirements. Installation and Maintenance Keeping it Simple Ease of installation is another critical aspect when choosing tube couplings. A well-designed coupling should facilitate straightforward installation processes, reducing time and labor costs. Furthermore, regular maintenance checks should be manageable. Couplings that incorporate features such as self-sealing technologies can provide further simplification by eliminating the need for sealing tape or additional welds, thus reducing maintenance efforts over time. The Digital Advantage Embracing Technology Many companies now offer digital interfaces that assist in the selection and ordering processes. These platforms often provide comprehensive data, including CAD models, pressure ratings, and material compatibility charts. Embracing these digital assets not only simplifies the purchasing process but also aids in ensuring that the right product is chosen for the specific application. Conclusion Making an Informed Decision In the age of rapid technological advancement and increased specialization, choosing the right 1/4 inch tube coupling is more than just a matter of specification matching. It is about understanding the application requirements, material compatibility, and installation considerations, all while ensuring compliance with industry standards. Invest time in selecting a reputable supplier and accessing expert advice, which can be pivotal in making an informed decision. After all, these small but mighty components play a critical role in the efficiency and reliability of entire systems. By adopting a strategic approach to selecting tube couplings, businesses can enhance performance, reduce maintenance costs, and ensure longevity in their operations.

Latest news

-

Understanding Tubing Crossover: Tools for Enhanced Oilfield OperationsNewsAug.08,2025

-

Tubing Pup Joint: The Ideal Choice for Oil and Gas OperationsNewsAug.08,2025

-

Tubing and Casing: Essential Components in Oil and Gas ProductionNewsAug.08,2025

-

Introduction to Tubing CouplingNewsAug.08,2025

-

Casing Pup Joint: The Essential Component for Oil and Gas OperationsNewsAug.08,2025

-

Casing Coupling: The Essential Link in Well ConstructionNewsAug.08,2025

Related Products