- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ئىيۇن . 26, 2024 16:26

Back to list

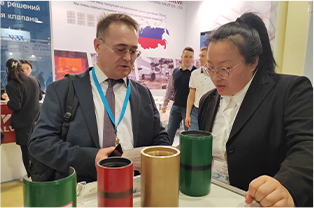

Sturdy 4 Stainless Steel Coupling for Robust Connections

The Significance of 4 Stainless Steel Couplings in Modern Industry

4 stainless steel couplings, often referred to as 316 stainless steel couplings, play a pivotal role in various industrial applications due to their exceptional durability and corrosion resistance. This type of stainless steel is known for its high strength and ability to withstand harsh environments, making it an ideal material for critical connection points in piping systems.

The primary function of a coupling is to join two pipes, tubes, or shafts together, allowing for the transfer of fluid or mechanical power. In the case of 4 stainless steel, the '4%' refers to the percentage of molybdenum present in the alloy, which significantly enhances its resistance to chloride-induced corrosion - a common issue in many industrial settings. The addition of molybdenum also increases the steel's tensile strength, making it suitable for high-pressure applications.

One of the key advantages of 4 stainless steel couplings is their adaptability. They can be easily fitted onto different pipe sizes and materials, providing a flexible solution for engineers and technicians. Their compatibility with both seamless and welded pipes, as well as their ability to connect pipes of dissimilar materials, makes them indispensable in industries where versatility is crucial.

Moreover, these couplings are designed to withstand extreme temperatures, ranging from sub-zero to high heat environments. This feature is particularly beneficial in sectors like oil and gas, chemical processing, and power generation, where temperature fluctuations are common.

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency 4 stainless steel coupling. Their resistance to wear and tear, along with their anti-corrosive properties, ensures a longer lifespan compared to couplings made from less durable materials. As a result, they offer a cost-effective solution in the long run, minimizing the need for frequent replacements or repairs.

In addition to their functional benefits, 4 stainless steel couplings also contribute to environmental sustainability. Their recyclability reduces waste and the carbon footprint associated with manufacturing new materials. Furthermore, their resistance to corrosion minimizes the risk of leaks, thus preventing potential environmental hazards.

In conclusion, 4 stainless steel couplings are more than just connectors; they are integral components that ensure the reliability and safety of industrial processes. Their unique combination of strength, corrosion resistance, and adaptability makes them a preferred choice across diverse industries. As technology continues to advance, the significance of these couplings in maintaining efficient and eco-friendly operations is only expected to grow.

4 stainless steel coupling. Their resistance to wear and tear, along with their anti-corrosive properties, ensures a longer lifespan compared to couplings made from less durable materials. As a result, they offer a cost-effective solution in the long run, minimizing the need for frequent replacements or repairs.

In addition to their functional benefits, 4 stainless steel couplings also contribute to environmental sustainability. Their recyclability reduces waste and the carbon footprint associated with manufacturing new materials. Furthermore, their resistance to corrosion minimizes the risk of leaks, thus preventing potential environmental hazards.

In conclusion, 4 stainless steel couplings are more than just connectors; they are integral components that ensure the reliability and safety of industrial processes. Their unique combination of strength, corrosion resistance, and adaptability makes them a preferred choice across diverse industries. As technology continues to advance, the significance of these couplings in maintaining efficient and eco-friendly operations is only expected to grow.

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency

The robustness of 4 stainless steel also contributes to reduced maintenance costs and increased operational efficiency 4 stainless steel coupling. Their resistance to wear and tear, along with their anti-corrosive properties, ensures a longer lifespan compared to couplings made from less durable materials. As a result, they offer a cost-effective solution in the long run, minimizing the need for frequent replacements or repairs.

In addition to their functional benefits, 4 stainless steel couplings also contribute to environmental sustainability. Their recyclability reduces waste and the carbon footprint associated with manufacturing new materials. Furthermore, their resistance to corrosion minimizes the risk of leaks, thus preventing potential environmental hazards.

In conclusion, 4 stainless steel couplings are more than just connectors; they are integral components that ensure the reliability and safety of industrial processes. Their unique combination of strength, corrosion resistance, and adaptability makes them a preferred choice across diverse industries. As technology continues to advance, the significance of these couplings in maintaining efficient and eco-friendly operations is only expected to grow.

4 stainless steel coupling. Their resistance to wear and tear, along with their anti-corrosive properties, ensures a longer lifespan compared to couplings made from less durable materials. As a result, they offer a cost-effective solution in the long run, minimizing the need for frequent replacements or repairs.

In addition to their functional benefits, 4 stainless steel couplings also contribute to environmental sustainability. Their recyclability reduces waste and the carbon footprint associated with manufacturing new materials. Furthermore, their resistance to corrosion minimizes the risk of leaks, thus preventing potential environmental hazards.

In conclusion, 4 stainless steel couplings are more than just connectors; they are integral components that ensure the reliability and safety of industrial processes. Their unique combination of strength, corrosion resistance, and adaptability makes them a preferred choice across diverse industries. As technology continues to advance, the significance of these couplings in maintaining efficient and eco-friendly operations is only expected to grow. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products