- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

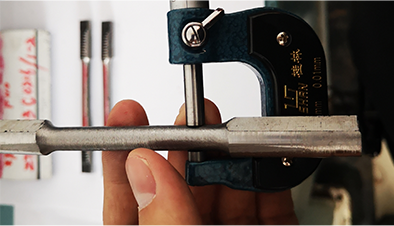

tubing collar

Understanding Tubing Collars in Oil and Gas Operations

In the oil and gas industry, tubing collars play a crucial role in the construction and functionality of well systems. These specialized components are an integral part of production tubing strings and are primarily used to facilitate the connection between different sections of tubing and to support various downhole equipment. Understanding the purpose, design, and application of tubing collars is essential for professionals in the field and those looking to deepen their knowledge of oil and gas operations.

A tubing collar is a type of joint that connects tubing sections in a well. It serves multiple purposes, including providing structural integrity to the entire tubing string, enabling the installation of downhole tools, and facilitating maintenance operations. The design of tubing collars can vary based on their intended use and the specific conditions of the well. Common types of collars include those designed for tension, compression, and bending loads, and they can be customized to suit both conventional and unconventional well applications.

One of the key functions of tubing collars is to create a seal between the tubing sections

. This sealing capability is vital to prevent fluid leaks and ensure that the reservoir fluid is efficiently transported to the surface. Collars often feature threading that allows them to be easily connected and disconnected from other components within the tubing string. Additionally, some collars incorporate features such as check valves or plugs to further enhance their functionality and adapt to specific operational needs.tubing collar

The installation of tubing collars is a critical step in the well completion process. During this process, careful considerations must be made regarding the depth and location of each collar. Factors such as downhole pressure, temperature, and the chemical composition of the fluids being produced can influence the choice of materials and design features for tubing collars. Typically, collars are made from high-strength steel or alloys that can withstand the harsh conditions encountered in petroleum reservoirs, ensuring durability and reliability over time.

Moreover, the maintenance of tubing collars is essential to the longevity of the well. Regular inspections and monitoring can detect wear and tear or any signs of failure before they lead to more significant problems. Failing to address issues in tubing collars can result in leaks, equipment failures, and costly interruptions in production. Consequently, operators often implement strict preventative maintenance schedules to ensure that all components, including tubing collars, are functioning optimally.

In summary, tubing collars are vital components in the oil and gas industry that facilitate the efficient transport of hydrocarbons from the reservoir to the surface. Their effectiveness hinges on careful design, selection of materials, and proper maintenance practices that align with the unique challenges of each well. As the industry continues to evolve with advancements in drilling technology and reservoir management, the role of tubing collars will undoubtedly remain significant, emphasizing the need for ongoing education and expertise in this essential area of well operations. Understanding tubing collars is not just about knowing their specifications; it's about appreciating their role in optimizing production and ensuring the safety and efficiency of oil and gas operations.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025