Mar . 07, 2025 06:55

Back to list

what are the differences between casing and tubing?

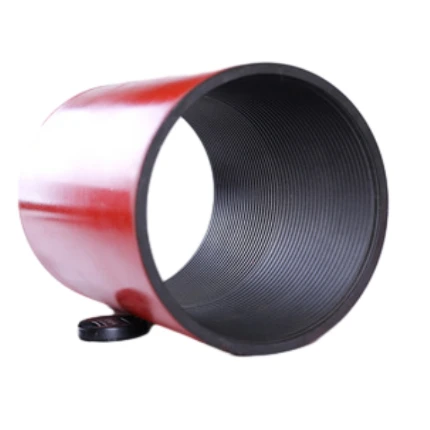

In the oil and gas industry, understanding the fundamental differences between casing and tubing is crucial. These two components, though seemingly similar, serve distinct roles within a drilling operation. From an engineering perspective, both elements are indispensable, yet they operate under different principles and purposes.

Material selection for casing and tubing is equally pivotal. Typically, casing is made from carbon steel or other high-strength materials capable of withstanding the weight and environmental pressures. Tubing also requires materials that can resist corrosion and handle high-pressure environments, often involving specialized alloys to extend the tubing's lifespan and reliability under harsh conditions. Technological advancements have also played a role in the evolution of casing and tubing materials and designs, enhancing their functionality and efficiency. Various innovative sealing methods, anti-corrosion techniques, and advanced coatings have been developed, aimed at improving longevity and reducing operational risks. For oil and gas companies, understanding these materials and their application scopes not only optimizes production but also significantly reduces costs and increases safety. A critical aspect often overlooked is the regulatory and environmental considerations that govern the casing and tubing processes. Industry professionals must adhere to strict guidelines and standards to ensure safety and environmental protection. This includes accurate testing of equipment before installation, continuous monitoring during operations, and comprehensive maintenance strategies. Ultimately, the differences between casing and tubing underscore their distinctive roles in well operations. While casing serves as the backbone by providing structure and protection, tubing acts as the lifeline, enabling the transport of valuable resources to the surface. A nuanced understanding of these differences not only enhances operational strategy but also ensures sustainability and efficiency, a crucial factor in today's environmentally conscious energy landscape. Understanding these elements with depth and precision demonstrates the capability to navigate the complex world of oil and gas production effectively.

Material selection for casing and tubing is equally pivotal. Typically, casing is made from carbon steel or other high-strength materials capable of withstanding the weight and environmental pressures. Tubing also requires materials that can resist corrosion and handle high-pressure environments, often involving specialized alloys to extend the tubing's lifespan and reliability under harsh conditions. Technological advancements have also played a role in the evolution of casing and tubing materials and designs, enhancing their functionality and efficiency. Various innovative sealing methods, anti-corrosion techniques, and advanced coatings have been developed, aimed at improving longevity and reducing operational risks. For oil and gas companies, understanding these materials and their application scopes not only optimizes production but also significantly reduces costs and increases safety. A critical aspect often overlooked is the regulatory and environmental considerations that govern the casing and tubing processes. Industry professionals must adhere to strict guidelines and standards to ensure safety and environmental protection. This includes accurate testing of equipment before installation, continuous monitoring during operations, and comprehensive maintenance strategies. Ultimately, the differences between casing and tubing underscore their distinctive roles in well operations. While casing serves as the backbone by providing structure and protection, tubing acts as the lifeline, enabling the transport of valuable resources to the surface. A nuanced understanding of these differences not only enhances operational strategy but also ensures sustainability and efficiency, a crucial factor in today's environmentally conscious energy landscape. Understanding these elements with depth and precision demonstrates the capability to navigate the complex world of oil and gas production effectively.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products