Feb . 20, 2025 03:56

Back to list

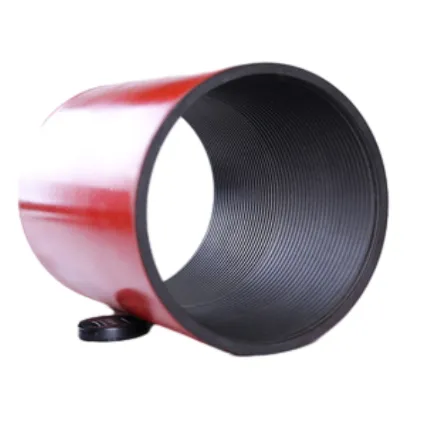

bull plug pressure rating

Bull plug pressure rating is a crucial aspect when dealing with various industrial applications, especially in the oil and gas sector. Understanding the pressure rating of a bull plug can mean the difference between the successful completion of a project and a catastrophic failure. This article provides valuable insights into bull plug pressure ratings, delving into real-world experiences, expert advice, and authoritative guidelines while maintaining a trust-centered focus.

Expertise in material science and engineering rated as imperative plays a key role in determining the suitable bull plug pressure rating. Engineers must consider factors such as thermal expansion, chemical reactivity, and fatigue life under cyclic loading. Case studies reveal that even the most seasoned professionals benefit from collaboration with materials experts to select bull plugs that match specific applications and environmental conditions. Industry standards, such as those from the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API), provide authoritative guidelines on pressure ratings for bull plugs. These standards ensure consistency and reliability across applications, making them an invaluable resource for professionals seeking to make informed decisions. Compliance with these standards not only enhances safety but also upholds the operational integrity of the piping systems. Trustworthiness in the context of bull plug pressure ratings stems from using certified products and adhering to documented installation and maintenance procedures. Companies often stress the importance of traceability and documentation in ensuring that every bull plug used in a project meets or exceeds the required pressure rating. By maintaining detailed records, organizations can quickly address any issues that arise, thereby minimizing downtime and optimizing operations. In conclusion, navigating the complexities of bull plug pressure ratings requires a blend of practical experience, specialized knowledge, and adherence to industry standards. By anchoring decisions in trusted expertise and authoritative guidance, professionals can effectively safeguard their operations against potential hazards and maintain peak performance levels. Through a commitment to quality and safety in the selection and use of bull plugs, industries can continue to operate confidently in even the most challenging high-pressure environments.

Expertise in material science and engineering rated as imperative plays a key role in determining the suitable bull plug pressure rating. Engineers must consider factors such as thermal expansion, chemical reactivity, and fatigue life under cyclic loading. Case studies reveal that even the most seasoned professionals benefit from collaboration with materials experts to select bull plugs that match specific applications and environmental conditions. Industry standards, such as those from the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API), provide authoritative guidelines on pressure ratings for bull plugs. These standards ensure consistency and reliability across applications, making them an invaluable resource for professionals seeking to make informed decisions. Compliance with these standards not only enhances safety but also upholds the operational integrity of the piping systems. Trustworthiness in the context of bull plug pressure ratings stems from using certified products and adhering to documented installation and maintenance procedures. Companies often stress the importance of traceability and documentation in ensuring that every bull plug used in a project meets or exceeds the required pressure rating. By maintaining detailed records, organizations can quickly address any issues that arise, thereby minimizing downtime and optimizing operations. In conclusion, navigating the complexities of bull plug pressure ratings requires a blend of practical experience, specialized knowledge, and adherence to industry standards. By anchoring decisions in trusted expertise and authoritative guidance, professionals can effectively safeguard their operations against potential hazards and maintain peak performance levels. Through a commitment to quality and safety in the selection and use of bull plugs, industries can continue to operate confidently in even the most challenging high-pressure environments.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products