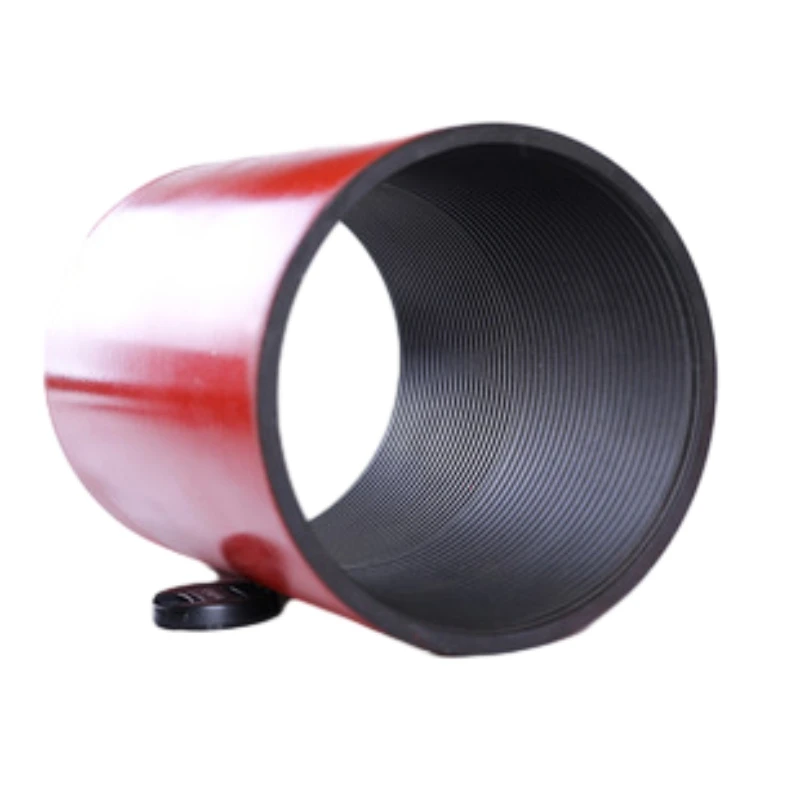

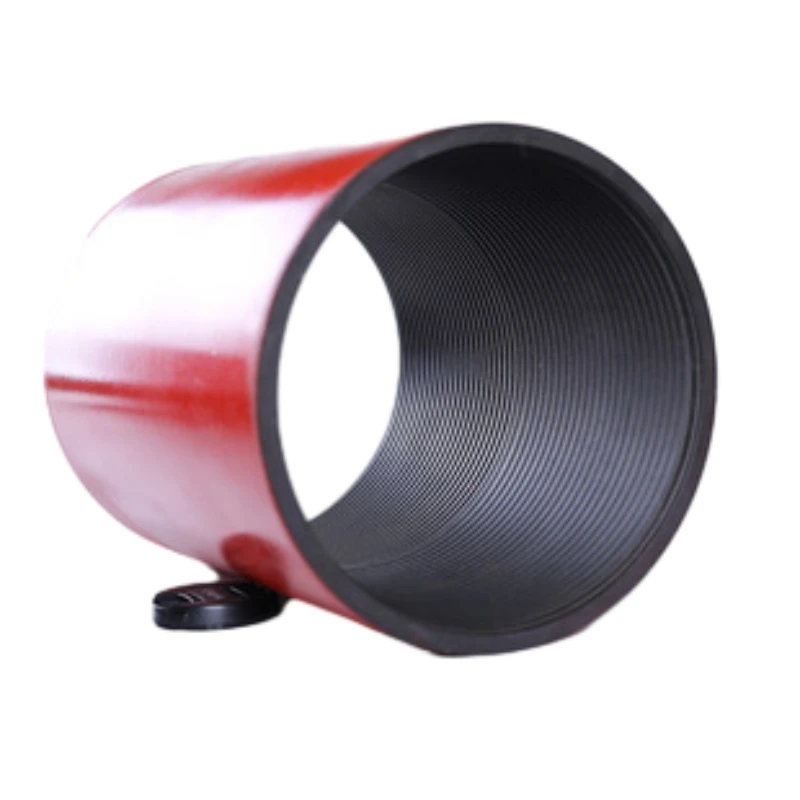

Casing Pup Joint

Casing pup joints are an essential component in the oil and gas industry, serving as a critical link between casing strings during drilling operations. These short sections of casing are used to adjust the length of the casing string to ensure optimal wellbore integrity and production efficiency. By connecting two casing strings together, casing pup joints help maintain the structural integrity of the wellbore, prevent casing wear and damage, and facilitate efficient well interventions. These components are typically made from high-strength steel and come in various lengths and connections to suit specific drilling requirements. Additionally, casing pup joints are designed to withstand high pressure and extreme conditions to ensure long-term well productivity and safety. Overall, these small but vital components play a crucial role in the oil and gas industry, contributing to the success and efficiency of drilling operations worldwide.

When it comes to the oil and gas industry, the casing pup joint plays a vital role in the drilling process. This essential piece of machinery is used to connect two pieces of casing with different threads, allowing for smooth and seamless operations. The thread on a casing pup joint is crucial as it ensures a secure connection that can withstand the high pressures and rigorous conditions of the drilling environment. It is important to select the right type of thread for the specific application, as using the wrong thread can lead to leaks, equipment failure, and even accidents. Proper maintenance and inspection of casing pup joints are also key factors in ensuring efficiency and safety during drilling operations. Overall, understanding the importance of the casing pup joint and its thread is essential for a successful and productive drilling process in the oil and gas industry.

When it comes to selecting the right casing pipe for oil and gas operations, API 5CT standards play a crucial role in ensuring the quality and performance of the product. The API 5CT specification sets minimum requirements for the design, material, chemical composition, and mechanical properties of casing pipes used in the oil and gas industry. These standards help to ensure the integrity and reliability of casing pipes, which are essential for protecting the wellbore and maintaining well control during drilling and production operations. By adhering to API 5CT standards, operators can be confident that the casing pipes they are using meet the necessary requirements for strength, durability, and corrosion resistance. Whether conducting drilling, cementing, or production activities, choosing casing pipes that comply with API 5CT standards is essential for maintaining the safety and efficiency of oil and gas operations.