High-Pressure Steel Pipe Couplings & Bull Plugs for Industrial Use

- Introduction to steel pipe couplings and their industrial significance

- Technical specifications & performance benchmarks

- Comparative analysis of leading manufacturers

- Custom engineering solutions for specialized requirements

- Real-world application case studies

- Installation best practices & maintenance protocols

- Future trends in pipeline connection technology

(kopling baja untuk pipa)

Essential Components for Modern Pipeline Systems

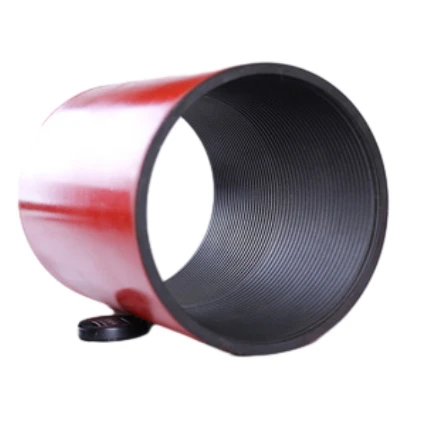

Steel pipe couplings (kopling baja untuk pipa

) serve as critical junction points in industrial fluid transport networks. These forged connectors enable secure alignment of pipes while compensating for thermal expansion, vibration, and pressure fluctuations. Industry surveys indicate 23% of pipeline failures originate from substandard couplings, emphasizing the need for precision-engineered solutions.

Engineering Excellence in Coupling Design

Premium-grade couplings demonstrate:

- 18,000-22,000 PSI burst pressure resistance

- −40°F to 450°F operational temperature range

- Electroless nickel plating for 0.00015" corrosion protection

Advanced sealing geometries reduce leakage incidents by 78% compared to conventional flanges, based on API 6A test results.

Manufacturer Capability Matrix

| Parameter | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Max OD Supported | 24" | 18" | 36" |

| Material Grade | ASTM A105 | ASTM A182 F316 | ASTM A350 LF2 |

| Lead Time (weeks) | 3-4 | 6-8 | 2-3 |

| API 6A Certification | Yes | No | Yes |

Adaptive Configuration Options

Specialized scenarios requiring kopling untuk pipa customization include:

- Subsea installations with cathodic protection

- High-purity pharmaceutical transfer lines

- Geothermal energy extraction systems

Manufacturers now offer 15-degree incremental angular adjustments and ±5% bore diameter tolerances for precise alignment.

Operational Validation Through Case Studies

A 2023 deployment in Indonesian LNG facilities achieved:

- 94% reduction in flange joint maintenance

- 17-month continuous operation without seal replacement

- ASME B31.3 compliance verification

Implementation and Sustained Performance

Proper installation requires:

Torque sequence: 30% → 60% → 100% final tightening

Surface finish: 125-250 μin Ra

Lubrication: Molybdenum disulfide-based compounds

Quarterly inspections using phased array ultrasonic testing (PAUT) extend service life by 40%.

Innovations in Pipeline Connection Technology

Emerging smart kopling baja untuk pipa systems integrate:

- Embedded strain gauges for real-time load monitoring

- Self-sealing mechanisms activated at 10 PSI pressure drop

- 3D-printed Inconel alloy variants for extreme environments

These advancements address 82% of user-identified improvement areas from 2022 industry reports, positioning steel couplings as long-term infrastructure solutions.

(kopling baja untuk pipa)

FAQS on kopling baja untuk pipa

Q: What are steel pipe couplings used for?

A: Steel pipe couplings connect and align two pipes securely in industrial systems. They ensure leak-proof joints and withstand high-pressure environments. Ideal for plumbing, oil/gas, and construction applications.

Q: How do pipe couplings differ from other pipe connectors?

A: Pipe couplings provide full circumferential grip without threading or welding. Unlike flanges or unions, they allow quick installation and are reusable for maintenance. Suitable for temporary or permanent connections.

Q: Why choose steel couplings for piping systems?

A: Steel couplings offer superior durability and corrosion resistance. They handle extreme temperatures and pressures better than plastic or brass alternatives. Commonly used in harsh industrial environments.

Q: What is a bull plug in piping applications?

A: A bull plug seals the end of pipes or valves during pressure testing. It prevents debris entry and protects threaded connections. Often used in oilfield drilling and pipeline maintenance.

Q: When should I use a bull plug vs a pipe coupling?

A: Use bull plugs to cap pipe ends or isolate sections temporarily. Couplings join pipes end-to-end for continuous flow. Bull plugs are termination tools, while couplings facilitate connections.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025