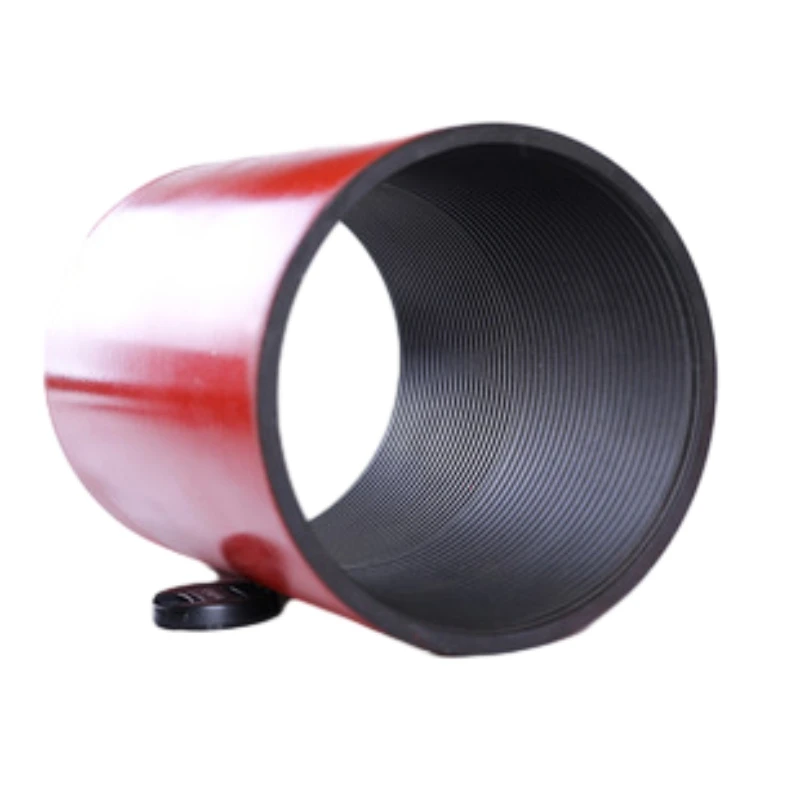

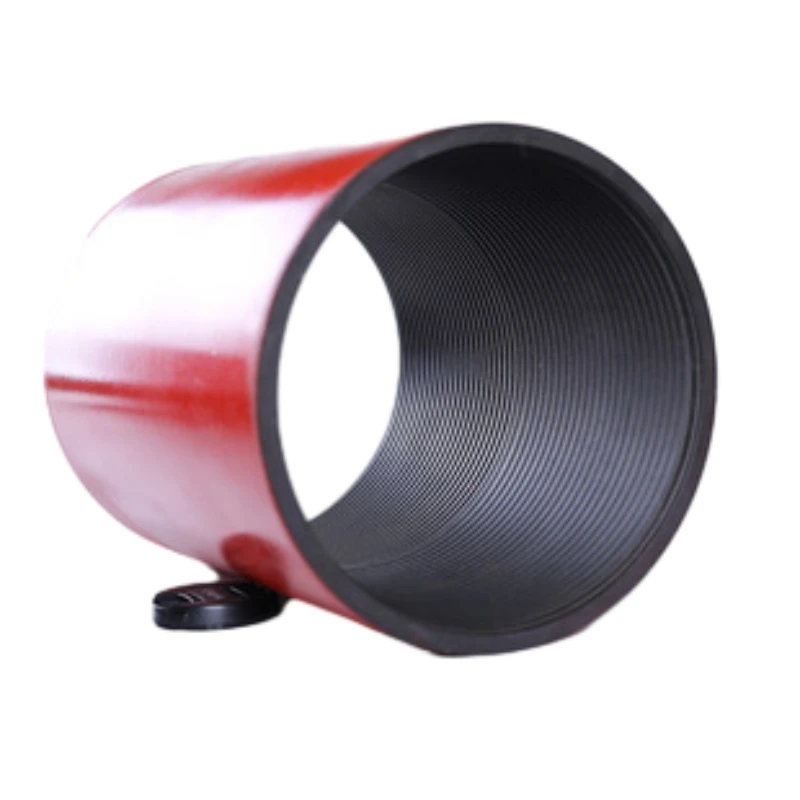

Caing Coupling

Casing couplings are a crucial component in the oil and gas industry, serving as the connection between individual sections of casing in a wellbore. These couplings are designed to provide a secure and leak-proof seal, ensuring the integrity of the well and protecting it from potential issues such as collapse or leakage. The selection of the right casing coupling is vital for the overall success of the drilling operation, as it must be able to withstand high pressure, corrosion, and extreme temperatures. Furthermore, casing couplings come in a variety of sizes and materials to accommodate different wellbore conditions and operational requirements. Whether it's a threaded coupling for easy installation or a premium connection for enhanced performance, the proper choice of casing coupling plays a significant role in ensuring the efficiency and safety of oil and gas drilling operations.

In addition to their structural role, casing couplings also play a key role in the overall efficiency and cost-effectiveness of drilling operations. By providing a reliable connection between casing sections, couplings help ensure the structural integrity of the well, reducing the risk of costly issues such as leaks or casing failure. Moreover, the use of high-quality casing couplings can also help improve drilling efficiency by allowing for quicker and more straightforward assembly of casing strings. This not only saves time during the drilling process but also minimizes downtime and associated costs. Additionally, the right choice of casing coupling can also help optimize well performance by reducing the risk of fluid migration or gas influx, improving overall well productivity and longevity.

In the oil and gas industry, casing and coupling standards play a crucial role in ensuring the safe and efficient operation of well systems. Casing refers to the steel pipe that is inserted into a wellbore to protect and support the surrounding rock formations. Couplings are the threaded connectors that link together individual casing sections, providing structural integrity and sealing against fluid leakage. The casing and coupling standards set out specific guidelines for the design, material, and dimensions of these components to ensure compatibility and performance in a variety of well conditions. By adhering to these standards, operators can minimize the risk of well failures, maintain well integrity, and optimize production efficiency. Overall, casing and coupling standards are essential tools in promoting the safety and success of oil and gas operations worldwide.