- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Led . 14, 2025 12:08

Back to list

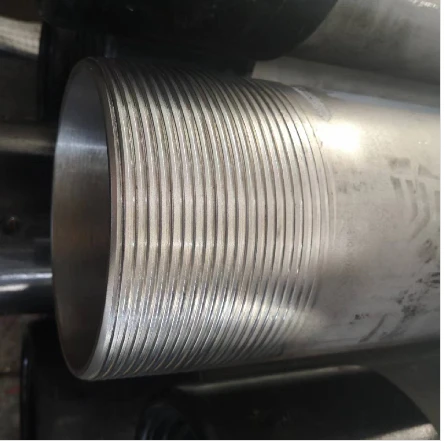

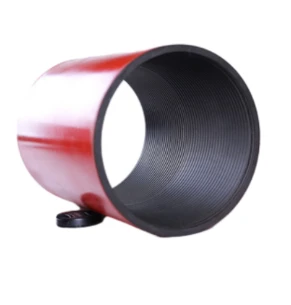

tubing coupling

In the world of industrial applications where precision and durability are paramount, seamless tubing coupling stands as a cornerstone for numerous industries such as oil and gas, automotive, and construction. Understanding the intricacies of seamless tubing and its coupling is crucial for professionals who seek efficiency and reliability in their operations.

The veracity of seamless tubing is underscored by its real-world applications. In the oil and gas sector, for example, seamless tubing is coupled to create pipelines that transport substances under extreme conditions with minimal risk of rupture. Similarly, in the automotive industry, seamless coupling in the brake systems ensures reliability and precision in vehicle safety mechanisms. Trustworthiness is further fortified through the use of advanced testing techniques such as non-destructive testing (NDT) to detect potential defects in the tubing or couplings before deployment. Hydrostatic testing, for example, ensures that the pressure capacity of the coupled tubing is validated beyond theoretical calculations. Choosing the right manufacturer and supplier is also a testament to trust. Companies with long-standing reputations, comprehensive warranties, and excellent customer service not only guarantee their product quality but also provide technical support and guidance throughout the product’s lifecycle. In conclusion, seamless tubing coupling is a specialized field that requires a blend of scientific knowledge, practical expertise, and strict adherence to industry standards. By prioritizing these elements, industries can ensure both the performance and safety of their operations, thereby enhancing their reputational authority and trust among clients and partners. As the demand for precision-engineered components continues to grow, the integral role of seamless tubing coupling will only become more prominent in driving industrial advancement.

The veracity of seamless tubing is underscored by its real-world applications. In the oil and gas sector, for example, seamless tubing is coupled to create pipelines that transport substances under extreme conditions with minimal risk of rupture. Similarly, in the automotive industry, seamless coupling in the brake systems ensures reliability and precision in vehicle safety mechanisms. Trustworthiness is further fortified through the use of advanced testing techniques such as non-destructive testing (NDT) to detect potential defects in the tubing or couplings before deployment. Hydrostatic testing, for example, ensures that the pressure capacity of the coupled tubing is validated beyond theoretical calculations. Choosing the right manufacturer and supplier is also a testament to trust. Companies with long-standing reputations, comprehensive warranties, and excellent customer service not only guarantee their product quality but also provide technical support and guidance throughout the product’s lifecycle. In conclusion, seamless tubing coupling is a specialized field that requires a blend of scientific knowledge, practical expertise, and strict adherence to industry standards. By prioritizing these elements, industries can ensure both the performance and safety of their operations, thereby enhancing their reputational authority and trust among clients and partners. As the demand for precision-engineered components continues to grow, the integral role of seamless tubing coupling will only become more prominent in driving industrial advancement.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products