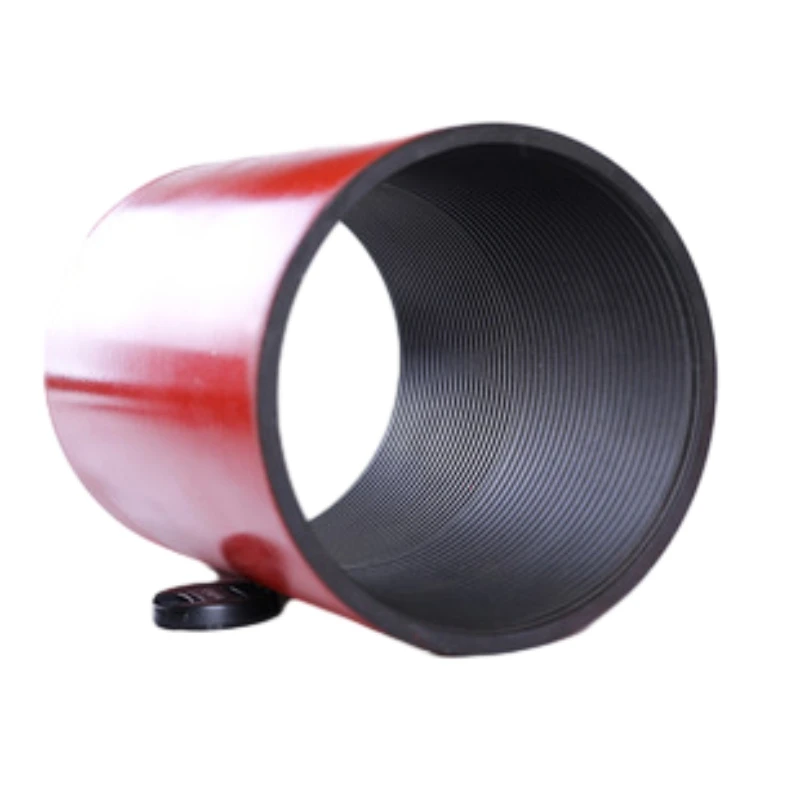

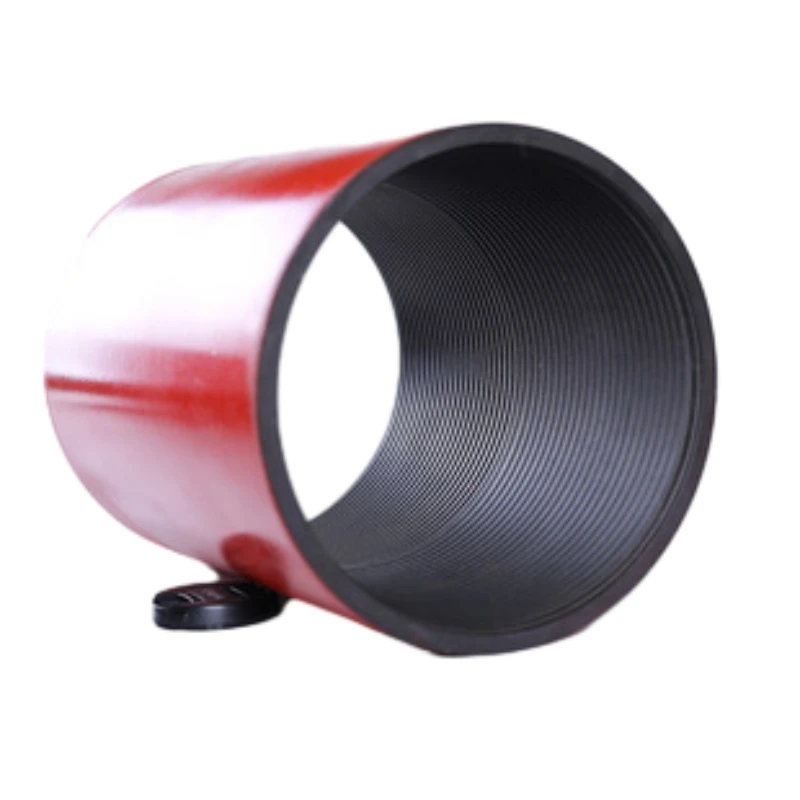

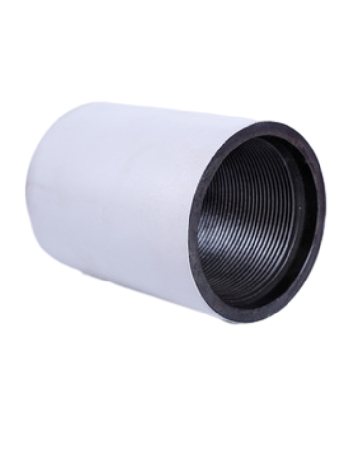

Tubing Coupling

Tubing couplings are essential components in oil and gas production operations, facilitating the connection of two pieces of tubing. These couplings come in various shapes and sizes, ensuring a secure and leak-proof seal between tubing sections. This crucial equipment plays a vital role in maintaining the integrity of the wellbore, preventing fluid leaks and protecting the environment. Tubing couplings are often made of high-quality materials such as carbon steel, stainless steel, or alloy steel, designed to withstand high-pressure and high-temperature conditions commonly encountered in oil and gas wells. Their durability and reliability make them a preferred choice for connecting tubing strings, ensuring the smooth and efficient flow of oil and gas to the surface. In conclusion, tubing couplings are indispensable components in the oil and gas industry, playing a significant role in maintaining the safety and efficiency of production operations.

The tubing coupling thread is a crucial component in the oil and gas industry, providing a vital connection between sections of tubing to ensure the seamless flow of resources. These threads are carefully designed to withstand high pressure and extreme conditions, such as those encountered in deep-sea drilling or hydraulic fracturing operations. The precise engineering of tubing coupling threads is essential to prevent leaks, maintain structural integrity, and ensure efficient operation of oil and gas wells. Without reliable tubing coupling threads, the entire extraction process would be at risk of failure, resulting in costly setbacks and potential environmental disasters. As technology continues to advance, the development of stronger, more durable tubing coupling threads is essential to meet the growing demands of the industry and ensure the safe and efficient extraction of oil and gas resources.

Tubing couplings play a critical role in the oil and gas industry, providing a connection between two sections of tubing to ensure the seamless flow of fluids. These couplings adhere to specific standards set by regulatory bodies to ensure safety, efficiency, and reliability in operations. The American Petroleum Institute (API) has established standard specifications for tubing couplings, outlining factors such as material requirements, dimensions, and performance testing criteria. By adhering to these standards, oil and gas companies can ensure the compatibility and quality of tubing couplings used in their operations, reducing the risk of leaks, failures, and environmental hazards. Additionally, standard tubing couplings allow for interchangeability among different manufacturers, providing flexibility in sourcing components without compromising performance. Overall, the establishment and adherence to standard specifications for tubing couplings are essential in maintaining operational integrity and safety within the oil and gas industry.