- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 20, 2025 03:20

Back to list

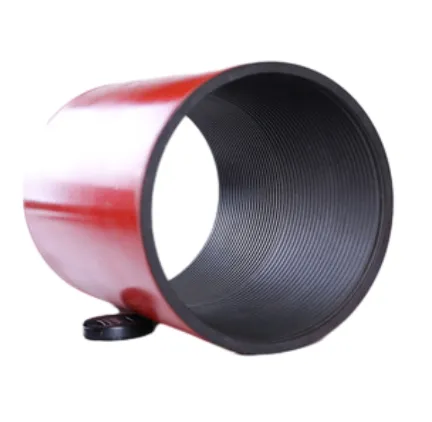

Tubing Coupling

In the world of construction and industrial piping systems, the importance of steel pipe couplings cannot be overstated. These components are integral in ensuring robust and secure connections, providing the necessary flexibility, and enhancing the efficiency of fluid transport systems. Understanding the intricacies of steel pipe couplings can significantly impact the performance and reliability of the infrastructure they support.

Expertise in selecting the right type of steel coupling is essential to match specific project requirements. For example, threaded steel couplings are commonly employed in low-pressure applications, providing a quick and simple connection method. On the other hand, welded couplings offer a more permanent solution and are often used in high-pressure systems where the risk of leakage must be minimized. Understanding these differences allows engineers and technicians to make informed decisions, enhancing system performance and safety. The authoritativeness of steel pipe couplings as a topic lies in their widespread utilization across various sectors. Industries such as construction, oil and gas, and water treatment rely heavily on these components for their infrastructure. Regulatory bodies often set standards for materials and installation, underscoring the critical role that steel pipe couplings play in ensuring compliance and safety. Furthermore, advancements in manufacturing technologies have led to the development of new steel alloys and protective coatings, extending the lifespan and functionality of couplings even further. Trustworthiness is a key consideration when selecting steel pipe couplings. Reputable manufacturers subject their products to rigorous testing and quality control to meet international standards. This commitment to excellence instills confidence in consumers, knowing that the couplings they install are dependable and durable. Moreover, choosing couplings from trusted sources mitigates the risks associated with inferior products, such as premature wear or catastrophic failure, safeguarding both personnel and assets. In conclusion, steel pipe couplings are vital components in the assembly of efficient and resilient piping systems. Their robust construction, adaptability to various conditions, and extensive application across industries underscore their importance. By focusing on experience, expertise, authoritativeness, and trustworthiness, stakeholders can make informed choices, ensuring optimal performance and longevity of their piping networks.

Expertise in selecting the right type of steel coupling is essential to match specific project requirements. For example, threaded steel couplings are commonly employed in low-pressure applications, providing a quick and simple connection method. On the other hand, welded couplings offer a more permanent solution and are often used in high-pressure systems where the risk of leakage must be minimized. Understanding these differences allows engineers and technicians to make informed decisions, enhancing system performance and safety. The authoritativeness of steel pipe couplings as a topic lies in their widespread utilization across various sectors. Industries such as construction, oil and gas, and water treatment rely heavily on these components for their infrastructure. Regulatory bodies often set standards for materials and installation, underscoring the critical role that steel pipe couplings play in ensuring compliance and safety. Furthermore, advancements in manufacturing technologies have led to the development of new steel alloys and protective coatings, extending the lifespan and functionality of couplings even further. Trustworthiness is a key consideration when selecting steel pipe couplings. Reputable manufacturers subject their products to rigorous testing and quality control to meet international standards. This commitment to excellence instills confidence in consumers, knowing that the couplings they install are dependable and durable. Moreover, choosing couplings from trusted sources mitigates the risks associated with inferior products, such as premature wear or catastrophic failure, safeguarding both personnel and assets. In conclusion, steel pipe couplings are vital components in the assembly of efficient and resilient piping systems. Their robust construction, adaptability to various conditions, and extensive application across industries underscore their importance. By focusing on experience, expertise, authoritativeness, and trustworthiness, stakeholders can make informed choices, ensuring optimal performance and longevity of their piping networks.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products