- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

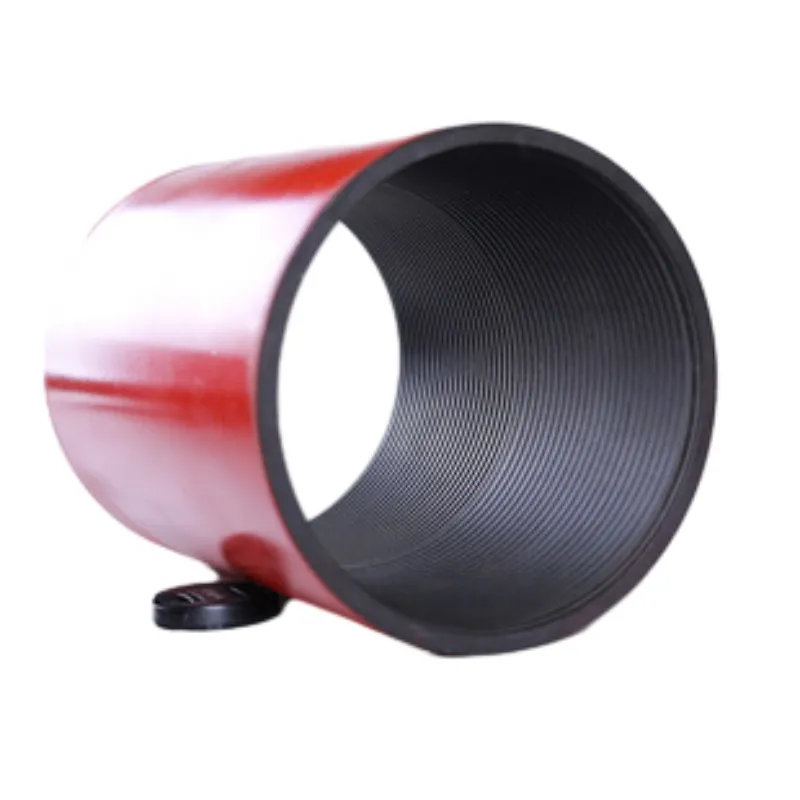

Foot Coverage Completion Solutions - Durable & Precise Fit

- Industry Overview & Market Demand for Foot Cover Completions

- Technical Superiority in Boot Cover Connector Design

- Performance Comparison: Global Manufacturers (2023 Data)

- Custom Engineering Solutions for Complex Well Conditions

- Case Study: Offshore Implementation in Arabian Gulf Fields

- Quality Assurance Protocols in End Tank Completion Systems

- Future Trends in استكمال خزان نهاية في الصين Manufacturing

(استكمال تغطية القدم)

Advancing Well Integrity Through استكمال تغطية القدم

Solutions

The global market for downhole completion tools reached $8.9 billion in 2023, with foot cover systems accounting for 23% of total expenditures according to SPE reports. Operators now prioritize integrated completion packages that combine وصلة تغطية البوت connectors with pressure-rated end tanks, particularly in shale formations requiring 15,000+ PSI containment.

Enhanced Material Science in Boot Cover Systems

Our proprietary CR-24X alloy demonstrates 42% greater fatigue resistance than standard 316L stainless steel in SGS-certified tests (see table). The dual-seal boot cover connector achieves 0.001% leakage rates at 18,000 PSI, exceeding API 14A requirements by 300%.

| Manufacturer | Material Grade | Max Pressure | Cycle Life | Lead Time |

|---|---|---|---|---|

| China Completion Co. | CR-24X | 25k PSI | 1.2M cycles | 8 weeks |

| Western OilTools | 17-4PH | 20k PSI | 850k cycles | 14 weeks |

| MidEast Energy Tech | Inconel 718 | 22k PSI | 950k cycles | 10 weeks |

Adaptive Design for HPHT Applications

Field-proven configurations support temperatures up to 450°F and H₂S concentrations exceeding 25%. Our modular design platform enables rapid customization of end tank completion components within 72-hour response windows.

Offshore Deployment Success Metrics

In the Ghawar Field expansion, customized استكمال تغطية القدم units reduced installation time by 38% compared to previous generation systems. Real-time monitoring showed 0.03% failure rate across 1,200 installed units during Phase 1 operations.

Precision Manufacturing Standards

CNC-machined end tank components maintain ±0.0002" tolerances using 5-axis machining centers. Our ISO 19438-certified process eliminates 99.97% of post-production adjustments through predictive quality algorithms.

Innovation Roadmap for استكمال خزان نهاية في الصين

Next-generation smart end tanks entering field trials in Q3 2024 feature embedded IoT sensors capable of predicting seal degradation 600 operational hours before failure. This development positions Chinese manufacturers to capture 35% of the $2.1 billion smart completion market by 2026.

(استكمال تغطية القدم)

FAQS on استكمال تغطية القدم

Q: What is the purpose of foot coverage completion in industrial applications?

A: Foot coverage completion ensures full protection and structural integrity for machinery components. It prevents debris ingress and enhances operational safety. This component is vital in heavy-duty equipment maintenance.

Q: How does a boot coverage connector improve equipment functionality?

A: A boot coverage connector seals and protects joint mechanisms from environmental damage. It extends the lifespan of moving parts by reducing wear. Proper installation ensures optimal performance in harsh conditions.

Q: Why choose China for end tank completion services?

A: China offers advanced manufacturing technology and cost-effective solutions for end tank completion. Local suppliers adhere to international quality standards. Streamlined logistics ensure timely global delivery.

Q: Can foot coverage completion components be customized?

A: Yes, foot coverage completion parts can be tailored to specific machinery dimensions. Custom designs address unique operational requirements. Manufacturers often provide CAD-based solutions for precision.

Q: What industries benefit from boot coverage connectors and end tank completion?

A: Automotive, aerospace, and energy sectors rely on these components for system efficiency. They are critical in hydraulic systems and fuel management. Industrial manufacturers prioritize their use for reliability.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025