- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Xan . 24, 2025 01:06

Back to list

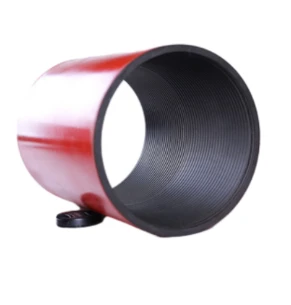

pasing pup joints

Pasing pup joints represent a niche but essential product category in the oil and gas industry, designed with precision to cater to specific operational needs on drilling sites. These specialized tools are pivotal in providing a bridge between drill pipes, leveraging a balance between strength, durability, and flexibility.

Trustworthiness, from a client perspective, stems from successful case studies and a track record of product excellence. Companies that employ pasing pup joints from reputable suppliers often report enhanced operational uptime and reduced instances of joint failure. When assessing manufacturers, decision-makers typically evaluate the historical performance data of pup joints and analyze case studies from similar operations. These reviews offer concrete evidence of reliability, bolstering trust in the product. Investment in research and development further highlights a commitment to improving pasing pup joint technology. Leading developers are continually seeking ways to enhance the design and functionality, incorporating feedback directly from the field to drive innovation. The integration of cutting-edge technology such as predictive analytics in material fatigue and advanced corrosion tests are examples of how manufacturers are pushing the boundaries to offer more reliable solutions. For businesses operating in high-stakes environments where downtime equates to significant financial loss, the choice of pasing pup joints can be a strategic one. Aligning with experienced manufacturers known for delivering expertise, adhering to stringent standards, and offering trustworthy products can be a critical component of a risk mitigation strategy. In conclusion, pasing pup joints remain an indispensable component in the drilling industry, offering both operational stability and safety. Customers seeking these products should prioritize manufacturers that offer proven expertise and authority in the field, demonstrated through compliance with international standards, a history of successful deployments, and a commitment to ongoing innovation. This strategic approach not only enhances operational efficiencies but also fortifies trust in the supply chain.

Trustworthiness, from a client perspective, stems from successful case studies and a track record of product excellence. Companies that employ pasing pup joints from reputable suppliers often report enhanced operational uptime and reduced instances of joint failure. When assessing manufacturers, decision-makers typically evaluate the historical performance data of pup joints and analyze case studies from similar operations. These reviews offer concrete evidence of reliability, bolstering trust in the product. Investment in research and development further highlights a commitment to improving pasing pup joint technology. Leading developers are continually seeking ways to enhance the design and functionality, incorporating feedback directly from the field to drive innovation. The integration of cutting-edge technology such as predictive analytics in material fatigue and advanced corrosion tests are examples of how manufacturers are pushing the boundaries to offer more reliable solutions. For businesses operating in high-stakes environments where downtime equates to significant financial loss, the choice of pasing pup joints can be a strategic one. Aligning with experienced manufacturers known for delivering expertise, adhering to stringent standards, and offering trustworthy products can be a critical component of a risk mitigation strategy. In conclusion, pasing pup joints remain an indispensable component in the drilling industry, offering both operational stability and safety. Customers seeking these products should prioritize manufacturers that offer proven expertise and authority in the field, demonstrated through compliance with international standards, a history of successful deployments, and a commitment to ongoing innovation. This strategic approach not only enhances operational efficiencies but also fortifies trust in the supply chain.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products