- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 13, 2024 12:16

Back to list

Bull plug pipe configuration

Understanding Bull Plug Pipe Layouts for Optimal Efficiency

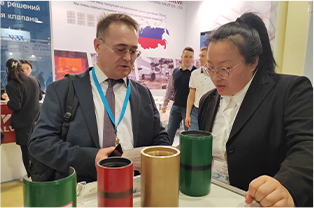

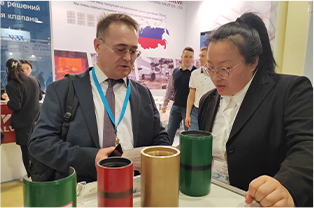

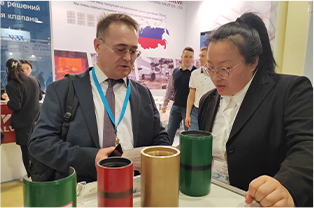

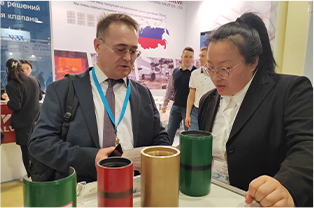

Bull plug pipe layouts, a specialized engineering concept, play a crucial role in the design and operation of industrial piping systems. This unique configuration is primarily employed to enhance flow dynamics, minimize pressure drop, and optimize fluid distribution within the pipeline network. The term bull plug refers to a solid cylindrical or conical device inserted into a pipeline to modify its internal geometry.

The bull plug, often made from durable materials like carbon steel or stainless steel, serves as a flow modifier. It's strategically placed within the pipe to alter the flow pattern, reducing turbulence and improving overall efficiency. The design of the plug, whether it's a simple cylindrical shape or a more complex conical form, depends on the specific application and the fluid properties being transported.

In a pipe layout, the positioning of the bull plugs is critical. They are usually installed at intervals along the pipeline, creating a series of controlled restrictions that help to stabilize the flow. By doing so, they can prevent issues like erosion, corrosion, and unwanted vibrations that could damage the pipe infrastructure over time. Moreover, these plugs can also assist in preventing slugging, a phenomenon where large fluid surges occur, causing potential safety hazards and equipment damage.

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability bull plug pipe layout. They can be tailored to suit various pipeline diameters and fluid types, making them a versatile solution for industries ranging from oil and gas to chemical processing and water treatment. Furthermore, they offer an economic benefit as they can potentially reduce the need for larger, more expensive pipe sizes by managing flow dynamics effectively.

However, designing an effective bull plug pipe layout requires a deep understanding of fluid dynamics, pipe mechanics, and material science. Engineers must consider factors such as flow rate, viscosity, pressure drop, and the physical characteristics of the bull plug itself. Computational Fluid Dynamics (CFD) simulations are often utilized to predict and analyze the flow behavior before implementing the layout in real-world applications.

In conclusion, the bull plug pipe layout is a sophisticated engineering strategy that leverages the power of geometry to optimize pipeline performance. It's a testament to how thoughtful design can significantly impact operational efficiency, safety, and cost-effectiveness in industrial processes. Despite its seemingly simple concept, the intricate interplay between bull plug design, placement, and fluid dynamics underscores the complexity and precision required in modern pipelining systems.

bull plug pipe layout. They can be tailored to suit various pipeline diameters and fluid types, making them a versatile solution for industries ranging from oil and gas to chemical processing and water treatment. Furthermore, they offer an economic benefit as they can potentially reduce the need for larger, more expensive pipe sizes by managing flow dynamics effectively.

However, designing an effective bull plug pipe layout requires a deep understanding of fluid dynamics, pipe mechanics, and material science. Engineers must consider factors such as flow rate, viscosity, pressure drop, and the physical characteristics of the bull plug itself. Computational Fluid Dynamics (CFD) simulations are often utilized to predict and analyze the flow behavior before implementing the layout in real-world applications.

In conclusion, the bull plug pipe layout is a sophisticated engineering strategy that leverages the power of geometry to optimize pipeline performance. It's a testament to how thoughtful design can significantly impact operational efficiency, safety, and cost-effectiveness in industrial processes. Despite its seemingly simple concept, the intricate interplay between bull plug design, placement, and fluid dynamics underscores the complexity and precision required in modern pipelining systems.

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability

One of the key advantages of bull plug pipe layouts is their adaptability bull plug pipe layout. They can be tailored to suit various pipeline diameters and fluid types, making them a versatile solution for industries ranging from oil and gas to chemical processing and water treatment. Furthermore, they offer an economic benefit as they can potentially reduce the need for larger, more expensive pipe sizes by managing flow dynamics effectively.

However, designing an effective bull plug pipe layout requires a deep understanding of fluid dynamics, pipe mechanics, and material science. Engineers must consider factors such as flow rate, viscosity, pressure drop, and the physical characteristics of the bull plug itself. Computational Fluid Dynamics (CFD) simulations are often utilized to predict and analyze the flow behavior before implementing the layout in real-world applications.

In conclusion, the bull plug pipe layout is a sophisticated engineering strategy that leverages the power of geometry to optimize pipeline performance. It's a testament to how thoughtful design can significantly impact operational efficiency, safety, and cost-effectiveness in industrial processes. Despite its seemingly simple concept, the intricate interplay between bull plug design, placement, and fluid dynamics underscores the complexity and precision required in modern pipelining systems.

bull plug pipe layout. They can be tailored to suit various pipeline diameters and fluid types, making them a versatile solution for industries ranging from oil and gas to chemical processing and water treatment. Furthermore, they offer an economic benefit as they can potentially reduce the need for larger, more expensive pipe sizes by managing flow dynamics effectively.

However, designing an effective bull plug pipe layout requires a deep understanding of fluid dynamics, pipe mechanics, and material science. Engineers must consider factors such as flow rate, viscosity, pressure drop, and the physical characteristics of the bull plug itself. Computational Fluid Dynamics (CFD) simulations are often utilized to predict and analyze the flow behavior before implementing the layout in real-world applications.

In conclusion, the bull plug pipe layout is a sophisticated engineering strategy that leverages the power of geometry to optimize pipeline performance. It's a testament to how thoughtful design can significantly impact operational efficiency, safety, and cost-effectiveness in industrial processes. Despite its seemingly simple concept, the intricate interplay between bull plug design, placement, and fluid dynamics underscores the complexity and precision required in modern pipelining systems. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products