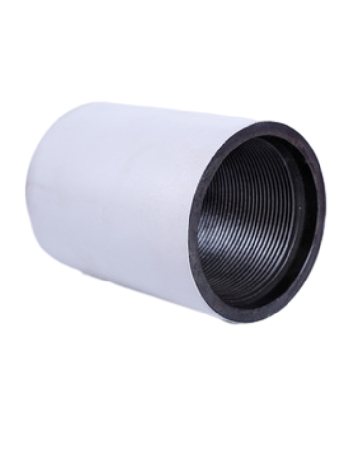

Kopling Tubing

Tubing kopling are essential components in oil and gas production operations, facilitating the connection of two pieces of tubing. These couplings come in various shapes and sizes, ensuring a secure and leak-proof seal between tubing sections. This crucial equipment plays a vital role in maintaining the integrity of the wellbore, preventing fluid leaks and protecting the environment. Tubing couplings are often made of high-quality materials such as carbon steel, stainless steel, or alloy steel, designed to withstand high-pressure and high-temperature conditions commonly encountered in oil and gas wells. Their durability and reliability make them a preferred choice for connecting tubing strings, ensuring the smooth and efficient flow of oil and gas to the surface. In conclusion, tubing couplings are indispensable components in the oil and gas industry, playing a significant role in maintaining the safety and efficiency of production operations.

Utas kopling pipa minangka komponen penting ing industri minyak lan gas, nyedhiyakake sambungan penting ing antarane bagean pipa kanggo njamin aliran sumber daya sing lancar. Utas iki dirancang kanthi ati-ati kanggo nahan tekanan dhuwur lan kahanan sing ekstrem, kayata sing ditemoni ing pengeboran laut jero utawa operasi fraktur hidrolik. Teknik sing tepat saka benang kopling pipa penting kanggo nyegah bocor, njaga integritas struktur, lan njamin operasi sumur minyak lan gas sing efisien. Tanpa benang kopling tabung sing dipercaya, kabeh proses ekstraksi bakal ana risiko gagal, nyebabake kemunduran larang lan bencana lingkungan sing potensial. Nalika teknologi terus maju, pangembangan benang kopling pipa sing luwih kuat lan luwih awet penting kanggo nyukupi panjaluk industri sing saya tambah lan njamin ekstraksi sumber minyak lan gas sing aman lan efisien.

Kopling pipa nduweni peran kritis ing industri minyak lan gas, nyedhiyakake sambungan antarane rong bagean pipa kanggo njamin aliran cairan sing lancar. Kopling iki tundhuk karo standar khusus sing disetel dening badan pangaturan kanggo njamin safety, efisiensi, lan linuwih ing operasi. American Petroleum Institute (API) wis netepake spesifikasi standar kanggo kopling pipa, njelasake faktor kayata syarat material, dimensi, lan kritéria tes kinerja. Kanthi netepi standar kasebut, perusahaan minyak lan gas bisa njamin kompatibilitas lan kualitas kopling pipa sing digunakake ing operasi, nyuda risiko bocor, gagal, lan bebaya lingkungan. Kajaba iku, kopling pipa standar ngidini pertukaran antarane manufaktur sing beda-beda, nyedhiyakake keluwesan ing sumber komponen tanpa kompromi kinerja. Sakabèhé, panyiapan lan ketaatan kanggo spesifikasi standar kanggo kopling pipa penting kanggo njaga integritas lan safety operasional ing industri minyak lan gas.