Feb . 16, 2025 13:53

Back to list

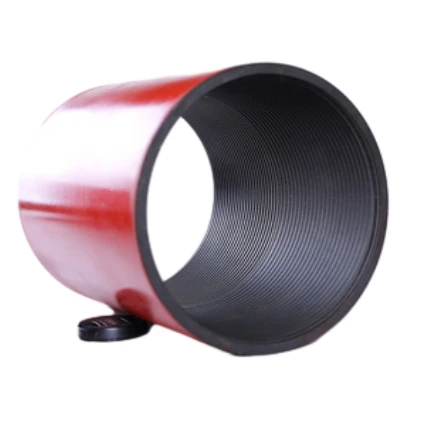

2 bull plug

The search for reliable and effective components in the oil and gas industry often leads professionals to focus on the quality and performance of essential parts like bull plugs. When exploring the keyword “2 bull plug”, it's vital to comprehend the various aspects that make these components indispensable in modern drilling operations.

Furthermore, insights from engineering professionals frequently underline the importance of precision and compatibility when integrating bull plugs into wider systems. Any mismatch or oversight can lead to leaks, inefficiencies, and potentially damaging consequences. Engineers leverage CAD software to model the dynamics of pipe systems, ensuring each bull plug fits perfectly into its intended pipeline junction. This precision engineering not only enhances operational efficiency but also extends the lifespan of the entire pipeline system, minimizing downtime and maintenance costs. Trustworthiness in the context of bull plugs is also built through comprehensive after-sales support from suppliers. The ability to offer guidance on installation, maintenance, and troubleshooting is invaluable. Top-tier suppliers position themselves as partners rather than mere vendors, providing detailed manuals, access to technical support teams, and perhaps even onsite installation assistance and inspection services. Moreover, case studies from major projects could provide authoritative context on the performance of 2-inch bull plugs in varied environments, from deep-sea drilling platforms to onshore rigs in harsh desert conditions. Highlighting scenarios where these products have successfully operated under extreme temperatures and pressures can help underscore their reliability and robustness. In summary, the keyword “2 bull plug” encompasses not just a product, but a crucial element of operational security and efficiency in the oil and gas industry. It is through a blend of real-world experience, technical expertise, authoritative manufacturing, and reliable support systems that these components can truly be relied upon to perform effectively. The bull plug, although small and often overlooked in the grand scope of an entire drilling operation, embodies the essential qualities that underpin safety, sustainability, and success in one of the most challenging sectors in the world. As a result, those selecting and implementing these components must consider every one of these factors to ensure the continued safety and efficacy of their operations.

Furthermore, insights from engineering professionals frequently underline the importance of precision and compatibility when integrating bull plugs into wider systems. Any mismatch or oversight can lead to leaks, inefficiencies, and potentially damaging consequences. Engineers leverage CAD software to model the dynamics of pipe systems, ensuring each bull plug fits perfectly into its intended pipeline junction. This precision engineering not only enhances operational efficiency but also extends the lifespan of the entire pipeline system, minimizing downtime and maintenance costs. Trustworthiness in the context of bull plugs is also built through comprehensive after-sales support from suppliers. The ability to offer guidance on installation, maintenance, and troubleshooting is invaluable. Top-tier suppliers position themselves as partners rather than mere vendors, providing detailed manuals, access to technical support teams, and perhaps even onsite installation assistance and inspection services. Moreover, case studies from major projects could provide authoritative context on the performance of 2-inch bull plugs in varied environments, from deep-sea drilling platforms to onshore rigs in harsh desert conditions. Highlighting scenarios where these products have successfully operated under extreme temperatures and pressures can help underscore their reliability and robustness. In summary, the keyword “2 bull plug” encompasses not just a product, but a crucial element of operational security and efficiency in the oil and gas industry. It is through a blend of real-world experience, technical expertise, authoritative manufacturing, and reliable support systems that these components can truly be relied upon to perform effectively. The bull plug, although small and often overlooked in the grand scope of an entire drilling operation, embodies the essential qualities that underpin safety, sustainability, and success in one of the most challenging sectors in the world. As a result, those selecting and implementing these components must consider every one of these factors to ensure the continued safety and efficacy of their operations.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products