- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Advancements in Perforated Pup Joints for Enhanced Oil and Gas Well Performance

The Role of Perforated Pup Joints in Oil and Gas Production

In the oil and gas industry, the intricacies of drilling and production are critical to maximizing efficiency and ensuring safety. One essential component used in this sector is the perforated pup joint, a specialized type of piping that plays a crucial role in the extraction process. Understanding the function and importance of perforated pup joints is vital for professionals in the field, as these joints contribute significantly to the overall productivity and effectiveness of drilling operations.

Defining Perforated Pup Joints

A pup joint is a length of pipe that is shorter than standard pipe sections, typically used to make up specific lengths of tubular goods in drilling operations. Perforated pup joints, as the name suggests, are equipped with perforations—small holes or slits—that allow fluids to flow in and out. These perforations are strategically designed to facilitate the passage of hydrocarbons from the reservoir to the surface while enabling the necessary pressures and fluid dynamics to be maintained during extraction.

Applications in Drilling Operations

Perforated pup joints are primarily utilized in various contexts within oil and gas drilling. They are often employed in conjunction with casing and tubing strings to optimize the flow of produced fluids. For instance, in the completion phase of well construction, these joints can be used to connect production tubing to the casing, ensuring that the flow of oil or gas from the reservoir is unimpeded.

Additionally, perforated pup joints can serve as an integral part of intervention operations. When operators need to address issues such as blockages or equipment malfunctions within the wellbore, these joints allow for easier access to the production zone, facilitating the deployment of tools and other devices necessary for maintenance and troubleshooting.

Advantages of Using Perforated Pup Joints

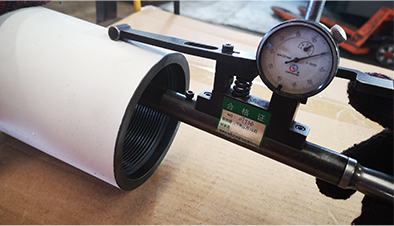

perforated pup joints

The adoption of perforated pup joints comes with several advantages that enhance operational efficiency. One of the primary benefits is their design flexibility; the perforation patterns and sizes can be customized based on specific reservoir characteristics and production requirements. This customization helps optimize fluid flow, thereby maximizing production rates.

Moreover, perforated pup joints can improve the safety of operations. By allowing for better management of flow rates and pressures within the well, these joints can help mitigate the risks associated with overpressure situations that may lead to blowouts or other hazardous conditions. Additionally, their use can reduce the need for more extensive and expensive modifications to drilling equipment, resulting in cost savings for operators.

Challenges and Considerations

Despite their advantages, the use of perforated pup joints is not without challenges. One primary concern is the potential for wear and tear on the joints due to the abrasive nature of some produced fluids, as well as erosion caused by high-velocity flows. Therefore, selecting the right materials and ensuring proper maintenance is essential to prolong the lifespan of perforated pup joints.

Furthermore, engineers must carefully evaluate the well conditions, including temperature, pressure, and chemical composition of fluids, to determine the most appropriate specifications for the perforated pup joints. Failing to account for these factors can lead to premature failures or inefficiencies in the production process.

Conclusion

In summary, perforated pup joints are crucial components in the oil and gas industry, serving to enhance the efficiency and safety of drilling and production operations. Their versatility and ability to be tailored to specific reservoir needs make them an invaluable asset, enabling better management of hydrocarbon flows while minimizing operational risks. As the industry continues to evolve, the importance of understanding and effectively utilizing perforated pup joints will only grow, underscoring their significance in the quest for efficient and sustainable oil and gas production.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025