- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 11, 2025 10:11

Back to list

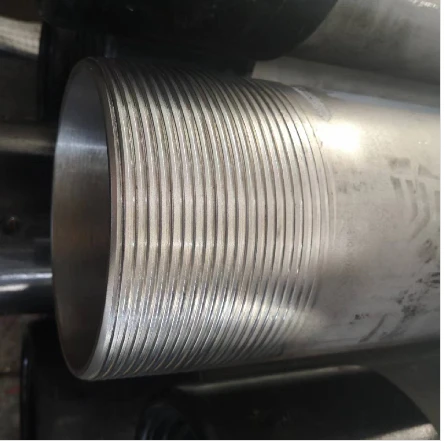

pup joint drilling

Pup joint drilling is an indispensable component in well drilling operations, offering flexibility and precise length adjustments in drill strings. A pup joint is essentially a short piece of tubing that comes in various lengths, designed to adjust the overall length of the drill string for better operational precision. Its importance cannot be overstated in the oil and gas industry, where every increment of the drill string's length requires meticulous calculation.

Moreover, the type of material used in manufacturing pup joints, usually ranging from carbon steel to stainless steel, must be in line with the operation's specific needs to avoid any chemical reactivity or unnecessary wear and tear. The choice of material is another demonstration of expertise, as it significantly impacts the lifecycle of the pup joint. Regular inspection and maintenance of pup joints are crucial to maximizing their operational lifespan. Drilling personnel often employ advanced techniques, such as non-destructive testing and magnetic particle inspection, to detect potential issues before they result in failures. These preventative measures showcase the unique intersection of experience and expertise, ensuring equipment reliability and operational efficiency. However, the choice isn't merely constrained to functionality; customization abilities offered by manufacturers add another layer of authority to their offerings. Custom-length pup joints ensure precise configurations tailored to each drilling operation's unique requirements, thereby enhancing the overall performance of the drill string. Expertise in configuring these tailor-made solutions is where seasoned professionals can significantly leverage their experience. In conclusion, when considering pup joints for drilling operations, it's crucial to integrate both technological advances and traditional expertise. By balancing these elements, operators can maintain trustworthiness and authoritativeness, ensuring not only operational success but also safety and efficiency in their drilling projects. A deep understanding and careful selection process will enhance operations, providing a seamless integration into complex drilling systems.

Moreover, the type of material used in manufacturing pup joints, usually ranging from carbon steel to stainless steel, must be in line with the operation's specific needs to avoid any chemical reactivity or unnecessary wear and tear. The choice of material is another demonstration of expertise, as it significantly impacts the lifecycle of the pup joint. Regular inspection and maintenance of pup joints are crucial to maximizing their operational lifespan. Drilling personnel often employ advanced techniques, such as non-destructive testing and magnetic particle inspection, to detect potential issues before they result in failures. These preventative measures showcase the unique intersection of experience and expertise, ensuring equipment reliability and operational efficiency. However, the choice isn't merely constrained to functionality; customization abilities offered by manufacturers add another layer of authority to their offerings. Custom-length pup joints ensure precise configurations tailored to each drilling operation's unique requirements, thereby enhancing the overall performance of the drill string. Expertise in configuring these tailor-made solutions is where seasoned professionals can significantly leverage their experience. In conclusion, when considering pup joints for drilling operations, it's crucial to integrate both technological advances and traditional expertise. By balancing these elements, operators can maintain trustworthiness and authoritativeness, ensuring not only operational success but also safety and efficiency in their drilling projects. A deep understanding and careful selection process will enhance operations, providing a seamless integration into complex drilling systems.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products