- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 04, 2025 05:47

Back to list

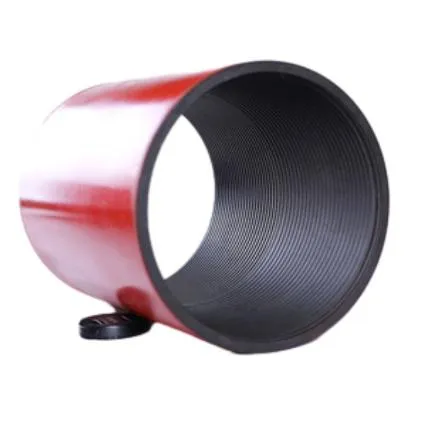

Tubing Coupling

Stainless steel couplings are an indispensable component in the world of mechanical and plumbing systems, hailed for their durability, reliability, and impeccable strength. Crafted from high-grade stainless steel, these couplings not only contribute to the seamless operation of various systems but also enhance their longevity, making them an ideal choice for both industrial and residential applications.

Stainless steel couplings come in various forms, each designed to fulfill specific roles within a system. Flexible couplings, for instance, allow for slight misalignment of connected components, absorbing shock and vibrations to protect the overall mechanism. On the other hand, rigid couplings provide a firm, immovable connection ideal for precise power transmission. Each type includes its own set of specifications and benefits, demanding a comprehensive understanding to ensure their effective application. Considering the lifecycle of a system, the maintenance of stainless steel couplings is relatively minimal compared to alternatives. Their innate composition resists the usual wear and tear caused by environmental factors, and with proper installation and periodic inspection, they can serve effectively for years. This trait not only appeals to project managers looking to minimize long-term maintenance costs but also aligns with sustainable practices by reducing waste and resource consumption. In recent years, technological advancements have enhanced the manufacturing processes of stainless steel couplings. Precision engineering and state-of-the-art metallurgy have improved their performance parameters, resulting in couplings that are lighter, stronger, and more adaptable than their predecessors. These innovations contribute to their growing popularity, as industries continue to demand solutions that meet the challenges of modern engineering requirements. Conclusively, stainless steel couplings epitomize a blend of experience, expertise, authority, and trustworthiness within the industrial sector. Their ability to meet demanding operational standards while offering economic and environmental benefits cements their status as an irreplaceable element of modern engineering. When chosen and utilized correctly, stainless steel couplings not only boost the efficiency of mechanical assemblies but also pave the way for innovation and enhanced performance across a multitude of applications. As industries evolve, so too will the design and application of stainless steel couplings, ensuring they remain a cornerstone of connectivity and reliability for years to come.

Stainless steel couplings come in various forms, each designed to fulfill specific roles within a system. Flexible couplings, for instance, allow for slight misalignment of connected components, absorbing shock and vibrations to protect the overall mechanism. On the other hand, rigid couplings provide a firm, immovable connection ideal for precise power transmission. Each type includes its own set of specifications and benefits, demanding a comprehensive understanding to ensure their effective application. Considering the lifecycle of a system, the maintenance of stainless steel couplings is relatively minimal compared to alternatives. Their innate composition resists the usual wear and tear caused by environmental factors, and with proper installation and periodic inspection, they can serve effectively for years. This trait not only appeals to project managers looking to minimize long-term maintenance costs but also aligns with sustainable practices by reducing waste and resource consumption. In recent years, technological advancements have enhanced the manufacturing processes of stainless steel couplings. Precision engineering and state-of-the-art metallurgy have improved their performance parameters, resulting in couplings that are lighter, stronger, and more adaptable than their predecessors. These innovations contribute to their growing popularity, as industries continue to demand solutions that meet the challenges of modern engineering requirements. Conclusively, stainless steel couplings epitomize a blend of experience, expertise, authority, and trustworthiness within the industrial sector. Their ability to meet demanding operational standards while offering economic and environmental benefits cements their status as an irreplaceable element of modern engineering. When chosen and utilized correctly, stainless steel couplings not only boost the efficiency of mechanical assemblies but also pave the way for innovation and enhanced performance across a multitude of applications. As industries evolve, so too will the design and application of stainless steel couplings, ensuring they remain a cornerstone of connectivity and reliability for years to come.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products