- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 31, 2025 01:34

Back to list

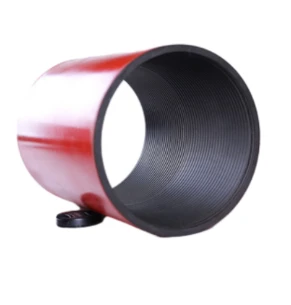

what is the difference between casing and tubing?

In the world of oil and gas drilling, understanding the distinct roles and characteristics of casing and tubing is crucial for operational efficiency and resource optimization. These two components are fundamental in the completion of wells, yet they serve different purposes and possess unique characteristics. Here’s a deeper look into the nuanced differences between casing and tubing based on practical experience and industry expertise.

The material selection further differentiates the two, with casing often manufactured from carbon steel and alloyed with chromium, especially in corrosive or high-temperature environments. Tubing may also be crafted from steel but can include corrosion-resistant alloys or even composite materials in environments where chemical resistance is paramount. The choice of materials for both casing and tubing is heavily influenced by expert knowledge of the expected pressures, temperatures, and fluid compositions to ensure longevity and efficiency. Furthermore, the economic implications of casing and tubing cannot be overlooked. Casing tends to incur higher costs due to its thickness, length, and the comprehensive installation process. Tubing costs can vary depending on the required specifications and material choices, but strategically selecting the right tubing can lead to increased production efficiencies and, consequently, better returns on investment. In terms of industry regulations and standards, both casing and tubing designs and installations adhere to strict guidelines set by global institutions such as the American Petroleum Institute (API). These standards ensure that all operations achieve a high level of safety, reliability, and performance. Professionals specializing in well engineering must be well-versed in these standards and integrate them into their planning and execution processes. In summary, the differences between casing and tubing are rooted in their distinct purposes, materials, and operational considerations. Understanding these differences is vital for industry professionals who aim to optimize drilling operations and ensure sustainable well production. By combining experience, expertise, authoritative standards, and trust in modern engineering practices, the effective utilization of casing and tubing lays the foundation for successful oil and gas extraction, meeting the demanding standards of today’s energy sector.

The material selection further differentiates the two, with casing often manufactured from carbon steel and alloyed with chromium, especially in corrosive or high-temperature environments. Tubing may also be crafted from steel but can include corrosion-resistant alloys or even composite materials in environments where chemical resistance is paramount. The choice of materials for both casing and tubing is heavily influenced by expert knowledge of the expected pressures, temperatures, and fluid compositions to ensure longevity and efficiency. Furthermore, the economic implications of casing and tubing cannot be overlooked. Casing tends to incur higher costs due to its thickness, length, and the comprehensive installation process. Tubing costs can vary depending on the required specifications and material choices, but strategically selecting the right tubing can lead to increased production efficiencies and, consequently, better returns on investment. In terms of industry regulations and standards, both casing and tubing designs and installations adhere to strict guidelines set by global institutions such as the American Petroleum Institute (API). These standards ensure that all operations achieve a high level of safety, reliability, and performance. Professionals specializing in well engineering must be well-versed in these standards and integrate them into their planning and execution processes. In summary, the differences between casing and tubing are rooted in their distinct purposes, materials, and operational considerations. Understanding these differences is vital for industry professionals who aim to optimize drilling operations and ensure sustainable well production. By combining experience, expertise, authoritative standards, and trust in modern engineering practices, the effective utilization of casing and tubing lays the foundation for successful oil and gas extraction, meeting the demanding standards of today’s energy sector.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products