- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

फेब . 12, 2025 21:38

Back to list

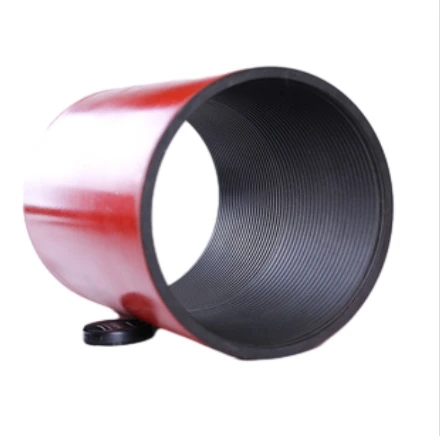

special clearance coupling

Achieving optimal machinery performance often demands components with precise specifications. In the world of mechanical engineering, the term special clearance coupling represents a pivotal component designed to meet the unique needs of high-precision systems. These couplings provide the vital connection between rotating components, ensuring smooth operation while accommodating specific clearance requirements imposed by complex machinery. By diving into the unique aspects, applications, and benefits of special clearance couplings, industries can enhance operational efficiency and reliability.

From an authoritative standpoint, special clearance couplings are subject to stringent industry standards and testing procedures. Leading manufacturers collaborate with industry experts to ensure compliance with regulations and to adopt cutting-edge technologies in their design processes. The rigorous quality checks not only serve to uphold industry standards but also enhance the trustworthiness of these components among consumers and businesses. In addition to the technological aspects, user experiences further validate the credibility of special clearance couplings. Case studies and testimonials provide evidence of their performance in real-world applications. Industries ranging from oil and gas to naval construction have reported significant improvements in machinery efficiency and reliability after switching to special clearance couplings. The tangible results achieved through these implementations build a strong case for their adoption, showcasing their role as a vital component in modern industrial systems. In conclusion, special clearance couplings represent a fusion of precision engineering, industry expertise, and reliable performance, making them indispensable in high-stakes applications. Their ability to cater to unique clearance requirements while maintaining alignment under challenging conditions underscores their value. As industries continue to push the envelope in machinery design and operation, the demand for such expertly crafted components will undoubtedly grow, reinforcing their status as an authoritative, trustworthy solution in the realm of mechanical engineering.

From an authoritative standpoint, special clearance couplings are subject to stringent industry standards and testing procedures. Leading manufacturers collaborate with industry experts to ensure compliance with regulations and to adopt cutting-edge technologies in their design processes. The rigorous quality checks not only serve to uphold industry standards but also enhance the trustworthiness of these components among consumers and businesses. In addition to the technological aspects, user experiences further validate the credibility of special clearance couplings. Case studies and testimonials provide evidence of their performance in real-world applications. Industries ranging from oil and gas to naval construction have reported significant improvements in machinery efficiency and reliability after switching to special clearance couplings. The tangible results achieved through these implementations build a strong case for their adoption, showcasing their role as a vital component in modern industrial systems. In conclusion, special clearance couplings represent a fusion of precision engineering, industry expertise, and reliable performance, making them indispensable in high-stakes applications. Their ability to cater to unique clearance requirements while maintaining alignment under challenging conditions underscores their value. As industries continue to push the envelope in machinery design and operation, the demand for such expertly crafted components will undoubtedly grow, reinforcing their status as an authoritative, trustworthy solution in the realm of mechanical engineering.

Next:

Latest news

-

Understanding Tubing Crossover: Tools for Enhanced Oilfield OperationsNewsAug.08,2025

-

Tubing Pup Joint: The Ideal Choice for Oil and Gas OperationsNewsAug.08,2025

-

Tubing and Casing: Essential Components in Oil and Gas ProductionNewsAug.08,2025

-

Introduction to Tubing CouplingNewsAug.08,2025

-

Casing Pup Joint: The Essential Component for Oil and Gas OperationsNewsAug.08,2025

-

Casing Coupling: The Essential Link in Well ConstructionNewsAug.08,2025

Related Products