- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਜਨਃ . 16, 2025 00:45

Back to list

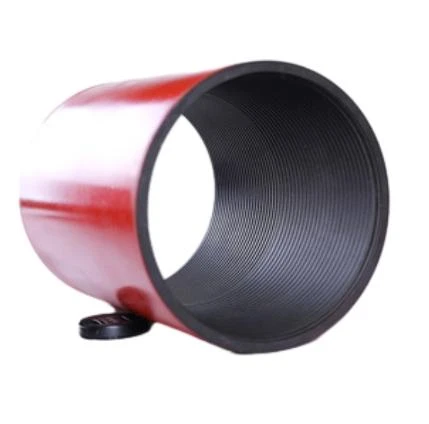

casing pup joint

Casing pup joints are integral components in the oil and gas industry, specifically within the operations of drilling and well completion. These short sections of pipe, generally ranging from a few feet to a couple of dozen in length, play a pivotal role in fine-tuning the depth of the string and solving connectivity challenges within the casing string.

Experience in deploying casing pup joints reveals several best practices that can optimize their use and extend their lifespan. Proper storage in a controlled environment, adherence to handling procedures during transportation, and regular inspection before deployment are all critical practices that can significantly impact the performance of these joints in field operations. In terms of authoritativeness, numerous studies and field reports have documented the successes and challenges associated with casing pup joints. These studies provide invaluable insights for continuous improvements in design and application. For instance, data on wear patterns and fatigue resistance have led to innovations in material compositions and treatment processes, thereby enhancing the joints' durability. Trustworthiness in casing pup joints is further cemented by ongoing collaborations between manufacturers and drilling companies. Feedback from the field is crucial in driving iterative improvements, ensuring the pup joints can meet the evolving demands of exploration in increasingly challenging environments, such as those with higher temperature gradients or more corrosive elements. In conclusion, casing pup joints are essential to the operational efficiency and safety of drilling operations. They epitomize the critical convergence of engineering expertise, rigorous manufacturing standards, and field experience. For industry professionals, understanding the nuances of these components—backed by authoritative data and trusted operational histories—transforms them from mere lengths of pipe into essential tools of precision in resource extraction. Whether you are a seasoned engineer or a newcomer to the industry, appreciating the significance of casing pup joints offers a clearer window into the complexities and innovations driving modern drilling and completion operations.

Experience in deploying casing pup joints reveals several best practices that can optimize their use and extend their lifespan. Proper storage in a controlled environment, adherence to handling procedures during transportation, and regular inspection before deployment are all critical practices that can significantly impact the performance of these joints in field operations. In terms of authoritativeness, numerous studies and field reports have documented the successes and challenges associated with casing pup joints. These studies provide invaluable insights for continuous improvements in design and application. For instance, data on wear patterns and fatigue resistance have led to innovations in material compositions and treatment processes, thereby enhancing the joints' durability. Trustworthiness in casing pup joints is further cemented by ongoing collaborations between manufacturers and drilling companies. Feedback from the field is crucial in driving iterative improvements, ensuring the pup joints can meet the evolving demands of exploration in increasingly challenging environments, such as those with higher temperature gradients or more corrosive elements. In conclusion, casing pup joints are essential to the operational efficiency and safety of drilling operations. They epitomize the critical convergence of engineering expertise, rigorous manufacturing standards, and field experience. For industry professionals, understanding the nuances of these components—backed by authoritative data and trusted operational histories—transforms them from mere lengths of pipe into essential tools of precision in resource extraction. Whether you are a seasoned engineer or a newcomer to the industry, appreciating the significance of casing pup joints offers a clearer window into the complexities and innovations driving modern drilling and completion operations.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products