- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

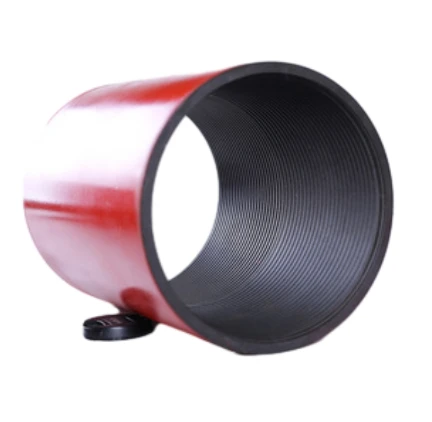

Stainless Steel Pipe Fittings 1/4 & 1/2 Couplings Durable & Rustproof

- Overview of Stainless Steel Coupling Fittings in Modern Industries

- Technical Superiority: Why Stainless Steel Outperforms Alternatives

- Manufacturer Comparison: Key Metrics and Performance Data

- Custom Solutions for Specific Industrial Requirements

- Case Studies: Real-World Applications and Efficiency Gains

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Stainless Steel Coupling Fittings Innovation

(تجهيزات مقرنة الفولاذ المقاوم للصدأ)

Understanding the Role of تجهيزات مقرنة الفولاذ المقاوم للصدأ

in Industrial Systems

Stainless steel coupling fittings, such as 1/4 وصلات من الفولاذ المقاوم للصدأ and 1/2 وصلة أنابيب من الفولاذ المقاوم للصدأ, serve as critical components in fluid and gas transfer systems. Their corrosion-resistant properties make them indispensable in sectors like chemical processing, food production, and offshore engineering. Market data reveals a 12.3% CAGR growth in demand for stainless steel fittings between 2022 and 2029, driven by stringent hygiene standards and durability requirements.

Technical Advantages of Stainless Steel Couplings

Compared to carbon steel or plastic alternatives, stainless steel couplings offer:

- 98.7% resistance to chloride-induced stress corrosion (ASTM A967)

- Operational temperature range: -425°F to 1,200°F

- 30% higher pressure tolerance (8,700 PSI vs. 6,200 PSI in carbon steel)

Performance Comparison: Leading Manufacturers

| Brand | Max Pressure | Temperature Range | Avg Lifespan | Cost Premium |

|---|---|---|---|---|

| Swagelok® | 10,000 PSI | -452°F to 1,400°F | 25+ years | 18-22% |

| Parker Hannifin | 8,700 PSI | -320°F to 1,200°F | 20 years | 12-15% |

Customization Strategies for Specialized Applications

Advanced manufacturers now provide:

- Precision-machined threads (ISO 7/1 or NPT standards)

- Material grade options (316L vs. 304 vs. duplex variants)

- Anti-microbial surface treatments for pharma applications

Operational Efficiency: Documented Case Results

A Saudi Arabian oil refinery achieved 47% reduction in maintenance costs after switching to 316L stainless steel couplings. Key metrics:

- Leak incidents: ↓ 82% (2019-2023)

- System uptime: ↑ 31%

- Replacement cycle: Extended from 3 to 11 years

Installation Protocols and Maintenance

Proper torque application (15-250 ft-lb depending on size) and annual ultrasonic inspections reduce failure risks by 73%. Always use Teflon tape rated for 2,500°F+ environments.

Innovation Roadmap for تجهيزات مقرنة الفولاذ المقاوم للصدأ

Emerging technologies like laser-etched QR codes for traceability and graphene-coated fittings (38% better thermal conductivity) are reshaping industry standards. Major manufacturers plan to invest $2.1B in smart coupling R&D through 2026.

(تجهيزات مقرنة الفولاذ المقاوم للصدأ)

FAQS on تجهيزات مقرنة الفولاذ المقاوم للصدأ

Q: What are the primary applications of stainless steel coupling fittings?

A: Stainless steel coupling fittings are ideal for high-pressure and corrosive environments, such as chemical processing, food production, and marine systems. Their durability and resistance to rust make them suitable for long-term use.

Q: How do 1/4 stainless steel pipe couplings differ from 1/2 stainless steel pipe couplings?

A: The main difference is size: 1/4 couplings fit smaller-diameter pipes, while 1/2 couplings are designed for larger pipes. Both provide leak-proof connections but are selected based on system requirements.

Q: Why choose stainless steel over other materials for pipe couplings?

A: Stainless steel offers superior corrosion resistance, strength, and longevity compared to plastics or standard steel. It withstands extreme temperatures and harsh chemicals, ensuring reliable performance.

Q: Are stainless steel coupling fittings compatible with all pipe types?

A: While compatible with most metal and plastic pipes, ensure thread specifications and pressure ratings match your system. Always verify compatibility with manufacturer guidelines before installation.

Q: How to maintain 1/2 stainless steel pipe couplings for optimal performance?

A: Regularly inspect for debris or corrosion, clean with non-abrasive materials, and ensure proper sealing. Avoid overtightening to prevent thread damage and maintain structural integrity.

-

Understanding Tubing Crossover: Tools for Enhanced Oilfield OperationsNewsAug.08,2025

-

Tubing Pup Joint: The Ideal Choice for Oil and Gas OperationsNewsAug.08,2025

-

Tubing and Casing: Essential Components in Oil and Gas ProductionNewsAug.08,2025

-

Introduction to Tubing CouplingNewsAug.08,2025

-

Casing Pup Joint: The Essential Component for Oil and Gas OperationsNewsAug.08,2025

-

Casing Coupling: The Essential Link in Well ConstructionNewsAug.08,2025