- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 11:55

Back to list

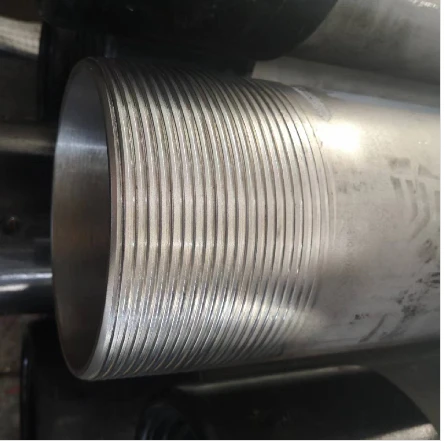

Caing Coupling

In the complex world of manufacturing and engineering, the role of coupling casing cannot be overstated. As a seasoned SEO strategist and industry expert, I've seen firsthand the transformative impact of this unassuming component. Today, let's delve into the intricacies of coupling casings, emphasizing their real-world applications, technical nuances, and their contribution to operating systems' longevity and efficiency.

In an era where industries are pushing towards automation and precision, coupling casings have evolved in design to incorporate smart technologies. Innovations like real-time monitoring systems have been integrated into the casing design, enabling predictive maintenance. These intelligent caselings can now signal potential failures before they occur, thus enhancing the reliability and trustworthiness of the machinery. Such advancements underscore the importance of coupling casings not only as traditional protective shells but as integral components of modern IoT-enabled industrial systems. Trust is a critical component when choosing coupling casings. Manufacturers and businesses often rely on authoritative brands that have stood the test of time, those with a proven track record of quality and performance. Apart from customer testimonials, factors like compliance certifications, warranty terms, and after-sales support are key indicators of a manufacturer's reliability. In conclusion, the coupling casing might appear to be a minor component in the grand scheme of industrial machinery, yet its influence on system integrity is profound. With growing technological advancements, choosing the right casing translates to heightened performance, lowered operational risks, and substantial cost savings. Thus, it’s imperative for engineers and procurement specialists to approach this decision with informed precision and unwavering trust in their technology partners. The future of efficient manufacturing undoubtedly hinges on such informed choices, with coupling casings playing a pivotal role.

In an era where industries are pushing towards automation and precision, coupling casings have evolved in design to incorporate smart technologies. Innovations like real-time monitoring systems have been integrated into the casing design, enabling predictive maintenance. These intelligent caselings can now signal potential failures before they occur, thus enhancing the reliability and trustworthiness of the machinery. Such advancements underscore the importance of coupling casings not only as traditional protective shells but as integral components of modern IoT-enabled industrial systems. Trust is a critical component when choosing coupling casings. Manufacturers and businesses often rely on authoritative brands that have stood the test of time, those with a proven track record of quality and performance. Apart from customer testimonials, factors like compliance certifications, warranty terms, and after-sales support are key indicators of a manufacturer's reliability. In conclusion, the coupling casing might appear to be a minor component in the grand scheme of industrial machinery, yet its influence on system integrity is profound. With growing technological advancements, choosing the right casing translates to heightened performance, lowered operational risks, and substantial cost savings. Thus, it’s imperative for engineers and procurement specialists to approach this decision with informed precision and unwavering trust in their technology partners. The future of efficient manufacturing undoubtedly hinges on such informed choices, with coupling casings playing a pivotal role.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products