Feb . 14, 2025 16:34

Back to list

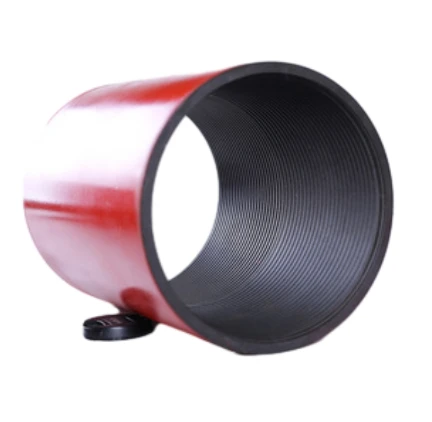

steel coupling

In the realm of industrial applications, steel coupling stands as a quintessential component that bridges machinery, offering seamless power transmission and enhancing overall efficiency. These integral devices ensure mechanical connectivity, aiding in the reduction of maintenance costs and prolonging the lifespan of equipment. Their relevance spans across multiple industries, which underscores the necessity of expert insight and authoritative knowledge in selecting and maintaining the right type of steel coupling for a specific application.

The role of expertise extends beyond the initial selection process. Regular monitoring and maintenance are paramount in prolonging the lifespan of steel couplings. This entails routine inspections to check for signs of wear and tear, such as unusual vibration or noise during operation, which are indicative of potential coupling failure. Implementing a proactive maintenance schedule is a testament to expertise and is vital in preventing unexpected equipment breakdowns, thus reinforcing trustworthiness in operational procedures. Moreover, emerging technologies have paved the way for advanced steel coupling designs that enhance operational efficiency and foster innovation within the industry. Developments such as smart couplings, which incorporate sensors for real-time monitoring, represent a leap in reliable power transmission solutions. These innovations not only provide data-driven insights into the performance of couplings but also affirm a strong commitment to enhancing operational trust through technology. The experience garnered from decades of engineering application signifies a dependable reference for new industries looking to implement steel coupling into their systems. Veteran professionals with extensive experience offer a glimpse into the nuances of successful coupling integration, accentuating the need for experienced voices in adopting these components. By leveraging real-world insights and industry-approved practices, companies can confidently navigate the complexities of coupling selection and maintenance. In conclusion, understanding steel coupling requires a multifaceted approach that values expertise, experience, authority, and trustworthiness. Each coupling must be seen as more than just a mechanical part—it is a vital cog in the machinery of industry that ensures uninterrupted workflow and operational efficiency. Ensuring the correct selection, regular maintenance, and embracing technological advancements are key strategies to optimizing their application. As industries continue to evolve, so too must the approaches to integrating these critical components, continually refining them to meet ever-changing demands and challenges.

The role of expertise extends beyond the initial selection process. Regular monitoring and maintenance are paramount in prolonging the lifespan of steel couplings. This entails routine inspections to check for signs of wear and tear, such as unusual vibration or noise during operation, which are indicative of potential coupling failure. Implementing a proactive maintenance schedule is a testament to expertise and is vital in preventing unexpected equipment breakdowns, thus reinforcing trustworthiness in operational procedures. Moreover, emerging technologies have paved the way for advanced steel coupling designs that enhance operational efficiency and foster innovation within the industry. Developments such as smart couplings, which incorporate sensors for real-time monitoring, represent a leap in reliable power transmission solutions. These innovations not only provide data-driven insights into the performance of couplings but also affirm a strong commitment to enhancing operational trust through technology. The experience garnered from decades of engineering application signifies a dependable reference for new industries looking to implement steel coupling into their systems. Veteran professionals with extensive experience offer a glimpse into the nuances of successful coupling integration, accentuating the need for experienced voices in adopting these components. By leveraging real-world insights and industry-approved practices, companies can confidently navigate the complexities of coupling selection and maintenance. In conclusion, understanding steel coupling requires a multifaceted approach that values expertise, experience, authority, and trustworthiness. Each coupling must be seen as more than just a mechanical part—it is a vital cog in the machinery of industry that ensures uninterrupted workflow and operational efficiency. Ensuring the correct selection, regular maintenance, and embracing technological advancements are key strategies to optimizing their application. As industries continue to evolve, so too must the approaches to integrating these critical components, continually refining them to meet ever-changing demands and challenges.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products