- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 22, 2025 04:17

Back to list

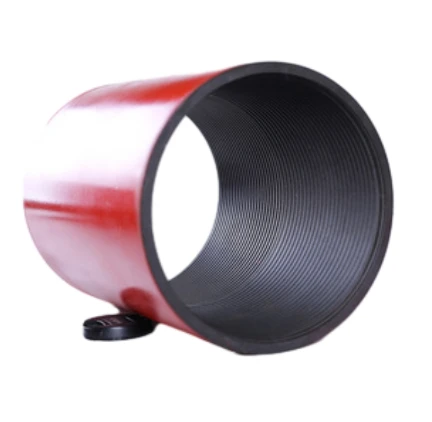

Caing Coupling

In the intricate world of oil and gas production, the API 5CT casing coupling stands as a pivotal component, indispensable for ensuring the safety and efficiency of drilling operations. With a career spanning over two decades in the field, I've witnessed firsthand the evolution and significance of casing couplings in oilfield operations. Drawing from this extensive experience, this article sheds light on the critical role and features of API 5CT casing couplings, providing a comprehensive guide for industry professionals seeking to optimize their drilling processes.

From a trustworthiness perspective, sourcing casing couplings from reputable manufacturers is crucial. Research and due diligence in supplier selection can prevent substandard products from compromising a project’s success. Certification and compliance with API standards serve as a benchmark for quality assurance. My professional connections within the industry underline that collaborations with accredited producers not only provide peace of mind but also contribute to overall project reliability. Furthermore, during my consultancy engagements, I've often emphasized the importance of routine inspection and maintenance of casing couplings to uphold operational efficiency. Regular non-destructive testing (NDT) can identify potential defects or wear patterns that, if left unattended, could result in costly repairs or operational halts. An expert approach involves integrating a robust NDT program into the maintenance schedule, thus extending the lifespan of the couplings and ensuring consistent performance. The authority of API 5CT casing couplings within industry standards cannot be understated. Their adoption reflects adherence to global best practices, with manufacturers continuously innovating to meet evolving industry demands. Through my participation in industry forums and workshops, it is evident that ongoing research and development are integral in enhancing the performance features of these couplings. This aligns with the industry's broader goal of achieving sustainable and safe resource extraction. In conclusion, the API 5CT casing coupling is more than a mere connection between pipes; it is a critical factor in the success and safety of drilling operations. Professionals engaged in the selection and use of these components must rely on their expertise and the trusted assurance of compliance with API standards. By prioritizing quality, precision engineering, and regular maintenance, the oil and gas industry can secure its operational endeavors while limiting environmental and financial risks.

From a trustworthiness perspective, sourcing casing couplings from reputable manufacturers is crucial. Research and due diligence in supplier selection can prevent substandard products from compromising a project’s success. Certification and compliance with API standards serve as a benchmark for quality assurance. My professional connections within the industry underline that collaborations with accredited producers not only provide peace of mind but also contribute to overall project reliability. Furthermore, during my consultancy engagements, I've often emphasized the importance of routine inspection and maintenance of casing couplings to uphold operational efficiency. Regular non-destructive testing (NDT) can identify potential defects or wear patterns that, if left unattended, could result in costly repairs or operational halts. An expert approach involves integrating a robust NDT program into the maintenance schedule, thus extending the lifespan of the couplings and ensuring consistent performance. The authority of API 5CT casing couplings within industry standards cannot be understated. Their adoption reflects adherence to global best practices, with manufacturers continuously innovating to meet evolving industry demands. Through my participation in industry forums and workshops, it is evident that ongoing research and development are integral in enhancing the performance features of these couplings. This aligns with the industry's broader goal of achieving sustainable and safe resource extraction. In conclusion, the API 5CT casing coupling is more than a mere connection between pipes; it is a critical factor in the success and safety of drilling operations. Professionals engaged in the selection and use of these components must rely on their expertise and the trusted assurance of compliance with API standards. By prioritizing quality, precision engineering, and regular maintenance, the oil and gas industry can secure its operational endeavors while limiting environmental and financial risks.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products