- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 11:20

Back to list

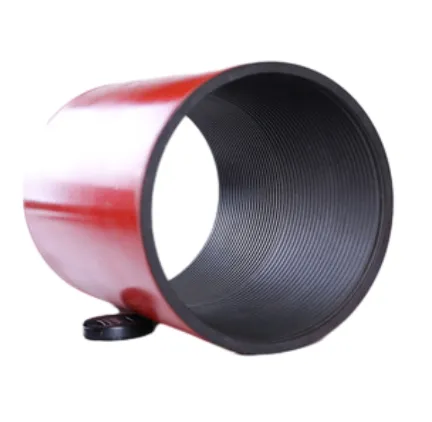

Coupling Casing Premium Quality for Reliable Performance

Coupling casings represent a critical component in numerous industrial applications, epitomizing the intersection of engineering precision, material science, and functionality. Used extensively in piping systems and machinery, they serve to connect shafts, enabling the seamless transmission of energy and torque. These components are essential for ensuring operation stability and mitigating the risk of mechanical failure.

Innovation in design and material science continues to propel the evolution of coupling casings. Recent advancements have introduced smart coupling casings equipped with sensors that provide real-time data on operational conditions. These smart casings allow for predictive maintenance, significantly reducing downtime and extending the operational life of mechanical systems. This trend of integrating IoT technologies exemplifies how coupling casings are not just static components but integral parts of a dynamic, interconnected system. For industries prioritizing efficiency and reliability, partnering with reputable suppliers known for their quality craftsmanship and adherence to industry standards is vital. Suppliers who are ISO certified and have a proven track record offer an assurance of product reliability and performance. Reviews and testimonials from other industry professionals can further validate a supplier's credibility and product quality. In conclusion, coupling casings may appear to be simple mechanical components, but their role in industrial applications is profound. They embody a blend of engineering expertise, precision manufacturing, and materials science. The future of these components lies in continued innovation and the integration of advanced technologies, driving industries towards greater efficiency and operational excellence. Carefully chosen and expertly installed, coupling casings can significantly enhance the performance and reliability of any mechanical system, proving their indispensable value in industrial operations.

Innovation in design and material science continues to propel the evolution of coupling casings. Recent advancements have introduced smart coupling casings equipped with sensors that provide real-time data on operational conditions. These smart casings allow for predictive maintenance, significantly reducing downtime and extending the operational life of mechanical systems. This trend of integrating IoT technologies exemplifies how coupling casings are not just static components but integral parts of a dynamic, interconnected system. For industries prioritizing efficiency and reliability, partnering with reputable suppliers known for their quality craftsmanship and adherence to industry standards is vital. Suppliers who are ISO certified and have a proven track record offer an assurance of product reliability and performance. Reviews and testimonials from other industry professionals can further validate a supplier's credibility and product quality. In conclusion, coupling casings may appear to be simple mechanical components, but their role in industrial applications is profound. They embody a blend of engineering expertise, precision manufacturing, and materials science. The future of these components lies in continued innovation and the integration of advanced technologies, driving industries towards greater efficiency and operational excellence. Carefully chosen and expertly installed, coupling casings can significantly enhance the performance and reliability of any mechanical system, proving their indispensable value in industrial operations.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products