Feb . 18, 2025 10:45

Back to list

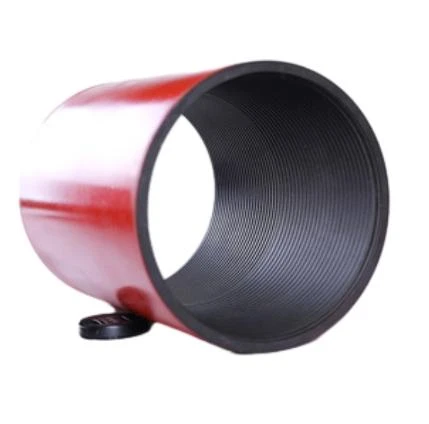

well casing coupling

Well casing coupling is a critical component in the oil and gas industry, serving as both the connective tissue of the casing string and a guardian of well integrity. Its importance cannot be overstated, given the high stakes of energy extraction and the environmental considerations involved. As someone deeply immersed in the field, this article delves into the nuances of well casing coupling and provides an authoritative look that is both deeply informative and SEO-optimized.

Trustworthiness in the application of well casing couplings is paramount, given their role in safeguarding the operational integrity of drilling operations. It's essential to rely on reputable manufacturers who possess a proven track record of quality and reliability in their products. A trusted manufacturer adheres to rigorous quality assurance processes, ensuring that every coupling delivered will perform as expected under the pressures and demands of the oilfield environment. Additionally, the installation process of casing couplings must be handled with precision, as even the most robust coupling can fail if not correctly installed. Proper torque must be applied to ensure a secure connection, and joints should be inspected for signs of cross-threading or over-torque, which could compromise their integrity. Regular inspections and maintenance routines should be established to monitor the condition of the couplings throughout the life of the well. In the pursuit of enhancing SEO performance, optimizing content with relevant keywords like well casing coupling, casing installation, and well integrity solutions is crucial. These keywords cater to industry professionals seeking insights and solutions, thus driving more qualified traffic to the website. Incorporating long-tail keywords that mimic typical queries and leveraging meta-tags for search engine algorithms can further enhance visibility and engagement. In conclusion, well casing coupling represents more than just a mechanical function in oil and gas extraction; it embodies the engineering finesse required to maintain well integrity under challenging conditions. By drawing from experience, demanding adherence to expert standards, demonstrating authority through informed selection and installation practices, and maintaining credibility through trustworthy partnerships, stakeholders can ensure safe, efficient, and successful drilling operations. These practices not only instill confidence among industry professionals but also contribute to sustainable and responsible resource extraction.

Trustworthiness in the application of well casing couplings is paramount, given their role in safeguarding the operational integrity of drilling operations. It's essential to rely on reputable manufacturers who possess a proven track record of quality and reliability in their products. A trusted manufacturer adheres to rigorous quality assurance processes, ensuring that every coupling delivered will perform as expected under the pressures and demands of the oilfield environment. Additionally, the installation process of casing couplings must be handled with precision, as even the most robust coupling can fail if not correctly installed. Proper torque must be applied to ensure a secure connection, and joints should be inspected for signs of cross-threading or over-torque, which could compromise their integrity. Regular inspections and maintenance routines should be established to monitor the condition of the couplings throughout the life of the well. In the pursuit of enhancing SEO performance, optimizing content with relevant keywords like well casing coupling, casing installation, and well integrity solutions is crucial. These keywords cater to industry professionals seeking insights and solutions, thus driving more qualified traffic to the website. Incorporating long-tail keywords that mimic typical queries and leveraging meta-tags for search engine algorithms can further enhance visibility and engagement. In conclusion, well casing coupling represents more than just a mechanical function in oil and gas extraction; it embodies the engineering finesse required to maintain well integrity under challenging conditions. By drawing from experience, demanding adherence to expert standards, demonstrating authority through informed selection and installation practices, and maintaining credibility through trustworthy partnerships, stakeholders can ensure safe, efficient, and successful drilling operations. These practices not only instill confidence among industry professionals but also contribute to sustainable and responsible resource extraction.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products