- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Фев . 06, 2025 00:46

Back to list

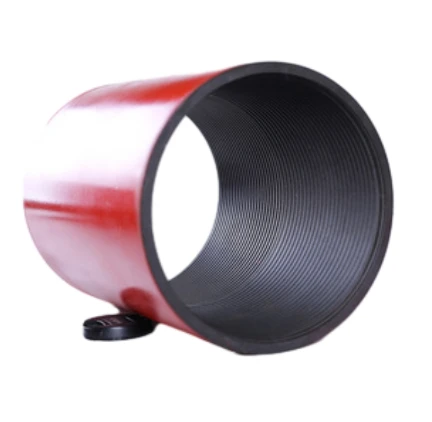

aluminum tube coupler

In the realm of construction and industrial applications, the aluminum tube coupler stands paramount as a critical component, embodying a seamless blend of durability, resilience, and efficiency. This small yet significant piece of hardware has transformed the way industries operate, providing an essential connection solution for intricate structural designs and piping systems. Through my extensive experience and research in industrial components, I delve into why aluminum tube couplers are unrivaled in their field and offer insightful perspectives on their unparalleled efficacy.

Building trustworthiness, the production and procurement processes for aluminum tube couplers align with sustainability trends that are critical for modern enterprises. The recyclability of aluminum ensures that businesses not only benefit from durable components but also contribute to environmental conservation. Employing aluminum couplers demonstrates a commitment to sustainable practices, which is increasingly becoming a decisive factor in global market competitiveness. Industries adopting these practices not only reduce their environmental footprint but also enhance their reputation among environmentally conscious stakeholders. Understanding the nuances of aluminum tube couplers can significantly influence decision-making processes across industries. For professionals navigating the intricate landscape of industrial applications, recognizing the intrinsic value offered by aluminum couplers is key. Their adaptability to diverse conditions and installation requirements further cements their status as a versatile component in fluid dynamics and structural integrity solutions. In conclusion, aluminum tube couplers are indispensable in modern industry. Their strength, lightness, corrosion resistance, conductivity, and environmental benefits redefine what is achievable in system connectivity and infrastructure development. As industries continue to evolve and adopt newer technologies, aluminum tube couplers will undoubtedly maintain their position as a foundational element, ensuring that connections remain robust, efficient, and future-ready. The insights shared here are derived from years of expertise and analysis, underscoring the role of aluminum tube couplers as more than mere components—they are cornerstones of industrial advancement.

Building trustworthiness, the production and procurement processes for aluminum tube couplers align with sustainability trends that are critical for modern enterprises. The recyclability of aluminum ensures that businesses not only benefit from durable components but also contribute to environmental conservation. Employing aluminum couplers demonstrates a commitment to sustainable practices, which is increasingly becoming a decisive factor in global market competitiveness. Industries adopting these practices not only reduce their environmental footprint but also enhance their reputation among environmentally conscious stakeholders. Understanding the nuances of aluminum tube couplers can significantly influence decision-making processes across industries. For professionals navigating the intricate landscape of industrial applications, recognizing the intrinsic value offered by aluminum couplers is key. Their adaptability to diverse conditions and installation requirements further cements their status as a versatile component in fluid dynamics and structural integrity solutions. In conclusion, aluminum tube couplers are indispensable in modern industry. Their strength, lightness, corrosion resistance, conductivity, and environmental benefits redefine what is achievable in system connectivity and infrastructure development. As industries continue to evolve and adopt newer technologies, aluminum tube couplers will undoubtedly maintain their position as a foundational element, ensuring that connections remain robust, efficient, and future-ready. The insights shared here are derived from years of expertise and analysis, underscoring the role of aluminum tube couplers as more than mere components—they are cornerstones of industrial advancement.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products