- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يانۋار . 14, 2025 12:37

Back to list

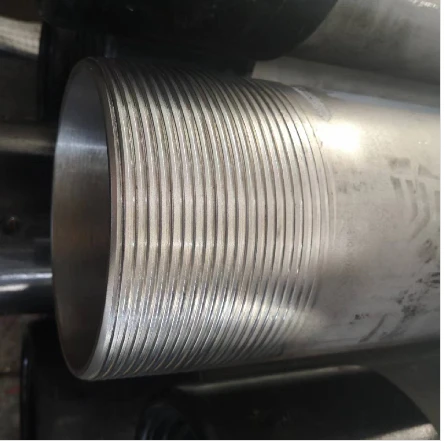

casing and tubing connections

Casing and tubing connections serve as the backbone for oil and gas exploration, facilitating operations across challenging environments. This intricate network of components, when optimized, can significantly enhance the efficiency and safety of drilling operations. With first-hand experience working alongside engineers and technicians in the field, the depth of insight into these connections becomes apparent, revealing their critical role in operational success.

Trustworthiness in the realm of casing and tubing connections hinges on a comprehensive approach to quality control and risk management. Real-world applications demand stringent testing and inspection protocols to mitigate the risks of failure, which can result in catastrophic environmental and financial consequences. The advent of digital technology has enhanced monitoring capabilities, allowing for real-time data analysis and predictive maintenance strategies that preempt issues before they escalate. Companies that adopt these advanced methodologies often gain a competitive advantage, providing reassurance to stakeholders through demonstrable improvements in safety and efficiency. The significance of casing and tubing connections in the oil and gas industry cannot be overstated. From my extensive observations, the ability to innovate and adapt within this domain is crucial. Whether through the adoption of novel materials, the implementation of cutting-edge digital tools, or the continuous refinement of testing methodologies, the potential for advancement remains vast. Industry leaders who prioritize research and development in connection technology not only enhance their operational capabilities but also position themselves as trusted partners in the pursuit of sustainable energy solutions.

Trustworthiness in the realm of casing and tubing connections hinges on a comprehensive approach to quality control and risk management. Real-world applications demand stringent testing and inspection protocols to mitigate the risks of failure, which can result in catastrophic environmental and financial consequences. The advent of digital technology has enhanced monitoring capabilities, allowing for real-time data analysis and predictive maintenance strategies that preempt issues before they escalate. Companies that adopt these advanced methodologies often gain a competitive advantage, providing reassurance to stakeholders through demonstrable improvements in safety and efficiency. The significance of casing and tubing connections in the oil and gas industry cannot be overstated. From my extensive observations, the ability to innovate and adapt within this domain is crucial. Whether through the adoption of novel materials, the implementation of cutting-edge digital tools, or the continuous refinement of testing methodologies, the potential for advancement remains vast. Industry leaders who prioritize research and development in connection technology not only enhance their operational capabilities but also position themselves as trusted partners in the pursuit of sustainable energy solutions.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products