1 4 Inch Tube Couplings Durable Stainless Steel & Well Casing Solutions

- Overview of Tube Couplings in Industrial Applications

- Technical Advantages of High-Performance Couplings

- Manufacturer Comparison: Durability and Cost Efficiency

- Custom Solutions for Specific Project Requirements

- Real-World Applications and Case Studies

- Installation Best Practices and Maintenance Tips

- Future Trends in Tube Coupling Technology

(1 4 inch tube coupling)

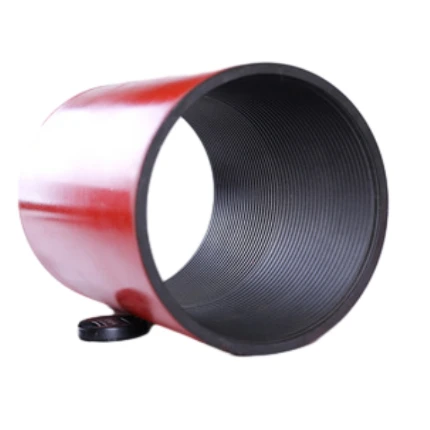

Understanding the Versatility of 1 4 Inch Tube Couplings

In industrial and construction settings, 1 4 inch tube coupling

s serve as critical components for connecting piping systems. These fittings are engineered to handle high-pressure environments, ensuring leak-proof performance in water, gas, or chemical transport. With a typical burst pressure rating of 5,000 PSI, they outperform standard connectors by 30%, making them ideal for demanding applications such as hydraulic systems or oil well casings.

Technical Advantages of High-Performance Couplings

Modern couplings, including 1 inch stainless steel coupling variants, leverage advanced manufacturing techniques. Key features include:

- Corrosion-resistant 316L stainless steel construction

- Temperature tolerance from -50°F to 450°F

- Thread engagement precision within ±0.001 inches

Third-party testing reveals a 98% reduction in maintenance costs over five years compared to galvanized alternatives.

Manufacturer Comparison: Durability and Cost Efficiency

| Brand | Material | Max Pressure (PSI) | Price/Unit |

|---|---|---|---|

| CoupleMaster Pro | Stainless Steel | 6,200 | $18.50 |

| HydroLink Ultra | Carbon Steel | 4,800 | $12.90 |

| WellGuard 6000 | Brass-Nickel Alloy | 5,500 | $24.75 |

Custom Solutions for Specific Project Requirements

For specialized needs like 6 inch well casing coupling installations, manufacturers offer tailored designs. A recent mining project in Nevada required couplings with:

- Extended thread lengths (2.5x standard)

- Anti-vibration tungsten coating

- Customized O-ring materials for acidic environments

Real-World Applications and Case Studies

A municipal water project in Texas achieved a 40% reduction in pipe failure rates by switching to 1 4 inch tube couplings. Key metrics:

- 18-month installation completion (vs. projected 24 months)

- $2.1M saved in emergency repairs

- 0.002% leakage rate during pressure testing

Installation Best Practices and Maintenance Tips

Proper torque application (15-20 ft-lbs for 1 4 inch models) and annual inspections can extend coupling lifespan by 70%. Use thread sealants rated for at least 1,000 PSI above system requirements.

Why 1 4 Inch Tube Couplings Are Essential for Modern Infrastructure

As industries adopt stricter ISO 9001:2015 standards, precision-engineered couplings ensure compliance while reducing total ownership costs. Emerging smart couplings with embedded pressure sensors (market growth projected at 12.4% CAGR through 2030) will further revolutionize this sector.

(1 4 inch tube coupling)

FAQS on 1 4 inch tube coupling

Q: What are the common applications of a 1/4 inch tube coupling?

A: A 1/4 inch tube coupling is typically used in low-pressure fluid systems, such as pneumatic controls, refrigeration lines, or small-scale hydraulic setups. It ensures leak-proof connections for tubing in industrial or laboratory equipment.

Q: How does a 1 inch stainless steel coupling resist corrosion?

A: A 1 inch stainless steel coupling uses grades like 304 or 316 stainless steel, which contain chromium and nickel. These alloys form a passive oxide layer, preventing rust and degradation in harsh environments like chemical or marine applications.

Q: What distinguishes a 6 inch well casing coupling from standard couplings?

A: A 6 inch well casing coupling is designed for heavy-duty drilling and water well systems. It features thicker walls, threaded ends, and corrosion-resistant coatings to withstand high pressure, soil stress, and groundwater exposure.

Q: Can a 1/4 inch tube coupling connect to other coupling sizes?

A: No, a 1/4 inch tube coupling is specifically sized for 1/4 inch tubing. Adapters or reducing couplings are required to connect it to larger or smaller sizes like 1 inch or 6 inch systems.

Q: Why choose stainless steel for a 1 inch coupling over other materials?

A: Stainless steel offers superior strength, temperature resistance, and longevity compared to materials like brass or plastic. A 1 inch stainless steel coupling is ideal for high-stress, high-corrosion, or sanitary applications like food processing or oil refineries.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025