Feb . 16, 2025 14:12

Back to list

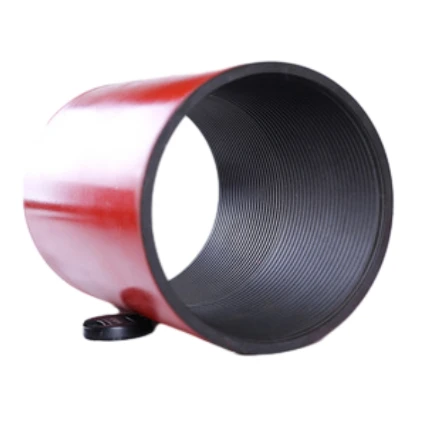

bull plug oil and gas

Bull plugs are integral components in the oil and gas industry, yet their significance is often overlooked amidst the myriad of tools and equipment used in exploration and production. These small, but crucial devices play a pivotal role in ensuring the efficiency and safety of drilling and completion processes. Understanding the purpose, application, and benefits of bull plugs can significantly enhance operational success in the oil and gas sector.

Expertise in the selection and application of bull plugs is essential for technicians and engineers in the field. Various factors, including the material specification, pressure rating, and thread compatibility, must be carefully considered to ensure optimal performance. Consulting with manufacturers and understanding the specific requirements of each project can greatly enhance the decision-making process, ensuring that the chosen bull plug fits seamlessly into the operational framework. Authoritative sources in the industry emphasize the importance of regular maintenance and inspection of bull plugs. This practice warrants that these devices remain in peak condition throughout their service life. Regular audits, including visual checks and pressure testing, can preemptively identify signs of wear or damage that could compromise system integrity. Prompt replacement of worn or damaged bull plugs is a prudent step that upholds operational safety and efficiency. Trust in bull plugs is bolstered by their compliance with industry standards and rigorous testing protocols. Many manufacturers subject their bull plugs to a battery of tests to verify pressure tolerance, material durability, and sealing efficacy. Certification from recognized bodies ensures that these components meet or exceed industry expectations, providing additional assurance to operators relying on their performance. In conclusion, bull plugs, though small, are indispensable to the oil and gas industry, offering robust solutions for sealing, safety, and sustainability in drilling and completion operations. Their expert application and diligent maintenance are paramount to capitalizing on their benefits, ensuring that oil and gas ventures proceed smoothly, safely, and efficiently. As technological advancements continue, the evolution of bull plug design and materials will further enhance their role in maximizing the efficacy of oil and gas operations.

Expertise in the selection and application of bull plugs is essential for technicians and engineers in the field. Various factors, including the material specification, pressure rating, and thread compatibility, must be carefully considered to ensure optimal performance. Consulting with manufacturers and understanding the specific requirements of each project can greatly enhance the decision-making process, ensuring that the chosen bull plug fits seamlessly into the operational framework. Authoritative sources in the industry emphasize the importance of regular maintenance and inspection of bull plugs. This practice warrants that these devices remain in peak condition throughout their service life. Regular audits, including visual checks and pressure testing, can preemptively identify signs of wear or damage that could compromise system integrity. Prompt replacement of worn or damaged bull plugs is a prudent step that upholds operational safety and efficiency. Trust in bull plugs is bolstered by their compliance with industry standards and rigorous testing protocols. Many manufacturers subject their bull plugs to a battery of tests to verify pressure tolerance, material durability, and sealing efficacy. Certification from recognized bodies ensures that these components meet or exceed industry expectations, providing additional assurance to operators relying on their performance. In conclusion, bull plugs, though small, are indispensable to the oil and gas industry, offering robust solutions for sealing, safety, and sustainability in drilling and completion operations. Their expert application and diligent maintenance are paramount to capitalizing on their benefits, ensuring that oil and gas ventures proceed smoothly, safely, and efficiently. As technological advancements continue, the evolution of bull plug design and materials will further enhance their role in maximizing the efficacy of oil and gas operations.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products