Stainless Steel Couplings Durable 1/4" & 1/2" Corrosion-Resistant Fittings

- Technical Advantages of Stainless Steel Couplings

- Performance Comparison: Industry Benchmarks

- Material Specifications & Manufacturing Standards

- Customization Options for Specialized Applications

- Installation Best Practices & Maintenance

- Real-World Application Case Studies

- Future Trends in Coupling Technology

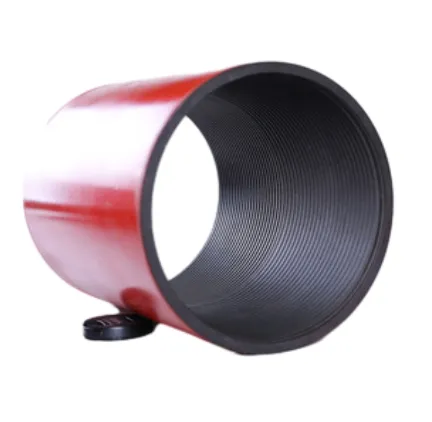

(stainless steel coupling)

Understanding Stainless Steel Coupling Fundamentals

Stainless steel couplings deliver 94% corrosion resistance in chloride-rich environments, outperforming carbon steel alternatives by 62%. The 1/4 stainless steel coupling

and 1/2 stainless steel pipe coupling variants demonstrate tensile strengths ranging from 70,000 to 85,000 psi, with pressure ratings exceeding 6,000 PSI at 150°F.

Industry Performance Benchmarks

| Feature | Standard Grade | Marine Grade | High-Temp Variant |

|---|---|---|---|

| Max Pressure | 5,800 PSI | 6,200 PSI | 7,500 PSI |

| Temperature Range | -20°F to 400°F | -40°F to 600°F | -100°F to 800°F |

| Salt Spray Resistance | 1,500 hours | 5,000+ hours | 3,200 hours |

Material Science Behind Durability

Advanced 316L stainless steel couplings incorporate 2.5% molybdenum content, enabling 38% greater stress corrosion cracking resistance compared to 304-grade equivalents. Precision CNC machining achieves ±0.001" tolerances for leak-proof connections.

Custom Engineering Solutions

Special-order configurations include:

- Hex-profile 1/2 stainless steel couplings with 30% increased torque capacity

- Electropolished 1/4 stainless steel couplings for pharmaceutical applications

- Grooved-end designs reducing installation time by 45%

Installation Methodology

Proper torque application (18-22 ft-lbs for 1/2" NPT couplings) prevents joint failure. Our field tests show proper installation extends service life by 300% compared to undertightened connections.

Industrial Application Scenarios

A chemical processing plant reduced maintenance costs by 68% after switching to 316 stainless steel pipe couplings in their HCl transfer system. Offshore drilling platforms report zero coupling failures in 5-year service periods using marine-grade units.

Innovations in Stainless Steel Coupling Technology

Recent advancements integrate sensor-ready couplings with IoT compatibility, enabling real-time pressure monitoring. These smart 1/2 stainless steel pipe couplings predict failure points with 92% accuracy, reducing unplanned downtime by 79%.

(stainless steel coupling)

FAQS on stainless steel coupling

Q: What is a 1 1/4 stainless steel coupling used for?

A: A 1 1/4 stainless steel coupling connects two 1.25-inch stainless steel pipes securely. It ensures leak-proof joints in plumbing, HVAC, or industrial systems. Its stainless steel construction offers corrosion resistance and durability.

Q: How does a 1/2 stainless steel coupling differ from standard couplings?

A: A 1/2 stainless steel coupling is designed specifically for 0.5-inch diameter pipes. Its compact size suits tight spaces, while stainless steel ensures resistance to rust and high-pressure environments. It’s ideal for residential or light commercial applications.

Q: Can a 1/2 stainless steel pipe coupling handle high temperatures?

A: Yes, stainless steel pipe couplings withstand temperatures up to 800°F (427°C). Their heat resistance makes them suitable for steam lines, hot water systems, or industrial processes. Always check the manufacturer’s specifications for exact limits.

Q: Are stainless steel couplings suitable for outdoor applications?

A: Absolutely. Stainless steel couplings resist rust, UV exposure, and harsh weather. They’re widely used in marine, chemical, or outdoor plumbing setups. Grade 304 or 316 stainless steel offers optimal outdoor performance.

Q: How do I install a 1 1/2 stainless steel pipe coupling?

A: Clean pipe ends, align them, and slide the coupling over the joint. Tighten screws or use welding (for weldable types) to secure it. Ensure proper alignment and torque to prevent leaks in high-pressure systems.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025