Feb . 15, 2025 18:50

Back to list

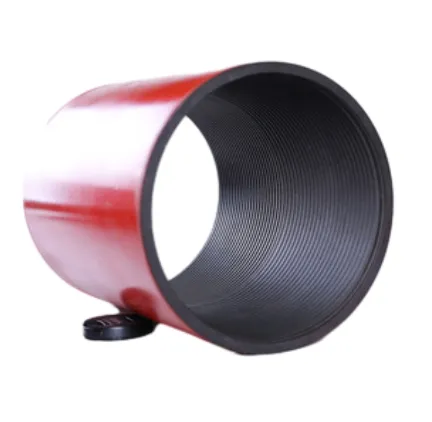

wholesale finished casing coupling

In the competitive landscape of oil and gas drilling, the efficiency and performance of your operations can hinge on seemingly small yet crucial components like casing couplings. Designed to connect separate sections of piping in a drill string, wholesale finished casing couplings play an instrumental role. This comprehensive overview dives into why these components are indispensable and what makes them stand out as a primal choice for professionals in the field.

Trustworthiness is another essential dimension underscoring the selection of casing couplings. Trust in a manufacturer grows with a consistent track record of delivering products that consistently perform in the field. Companies often back their couplings with robust warranty policies and customer service support, reinforcing their commitment to customer satisfaction and reliability. Furthermore, sourcing casing couplings via wholesale offers distinct advantages. Firstly, bulk purchasing often leads to cost efficiencies, which are crucial in the capital-intensive oil and gas industry. Secondly, wholesale relationships with trusted manufacturers ensure a steady supply chain, minimizing the risk of operational halts due to parts shortages. Thirdly, wholesale dealings often facilitate direct lines of communication with suppliers, enhancing the responsiveness to specific needs or adjustments. Regarding sustainability, leading casing coupling manufacturers are increasingly incorporating eco-friendly practices in their production processes. Efficient use of materials, minimized emissions, and recycling initiatives reflect a growing industry commitment to reducing the environmental impact of oil and gas operations. Moreover, the global nature of oil and gas operations demands couplings that can perform in diverse conditions, from the freezing temperatures of Arctic regions to the sweltering heat of desert landscapes. Reliable casing couplings must consistently deliver across such varied conditions, showcasing versatility and robustness. In conclusion, the role of wholesale finished casing couplings in oil and gas operations cannot be understated. Their contribution to maintaining structural integrity and operational efficiency is indispensable. Rich in expertise, manufactured to exacting standards, and delivered with the backing of experience and authority, these components remain a linchpin in the energy sector infrastructure. As the industry continues to evolve, embracing new technologies and sustainable practices, casing couplings will undoubtedly advance, meeting new challenges with refined expertise and unwavering reliability.

Trustworthiness is another essential dimension underscoring the selection of casing couplings. Trust in a manufacturer grows with a consistent track record of delivering products that consistently perform in the field. Companies often back their couplings with robust warranty policies and customer service support, reinforcing their commitment to customer satisfaction and reliability. Furthermore, sourcing casing couplings via wholesale offers distinct advantages. Firstly, bulk purchasing often leads to cost efficiencies, which are crucial in the capital-intensive oil and gas industry. Secondly, wholesale relationships with trusted manufacturers ensure a steady supply chain, minimizing the risk of operational halts due to parts shortages. Thirdly, wholesale dealings often facilitate direct lines of communication with suppliers, enhancing the responsiveness to specific needs or adjustments. Regarding sustainability, leading casing coupling manufacturers are increasingly incorporating eco-friendly practices in their production processes. Efficient use of materials, minimized emissions, and recycling initiatives reflect a growing industry commitment to reducing the environmental impact of oil and gas operations. Moreover, the global nature of oil and gas operations demands couplings that can perform in diverse conditions, from the freezing temperatures of Arctic regions to the sweltering heat of desert landscapes. Reliable casing couplings must consistently deliver across such varied conditions, showcasing versatility and robustness. In conclusion, the role of wholesale finished casing couplings in oil and gas operations cannot be understated. Their contribution to maintaining structural integrity and operational efficiency is indispensable. Rich in expertise, manufactured to exacting standards, and delivered with the backing of experience and authority, these components remain a linchpin in the energy sector infrastructure. As the industry continues to evolve, embracing new technologies and sustainable practices, casing couplings will undoubtedly advance, meeting new challenges with refined expertise and unwavering reliability.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products