Feb . 16, 2025 09:32

Back to list

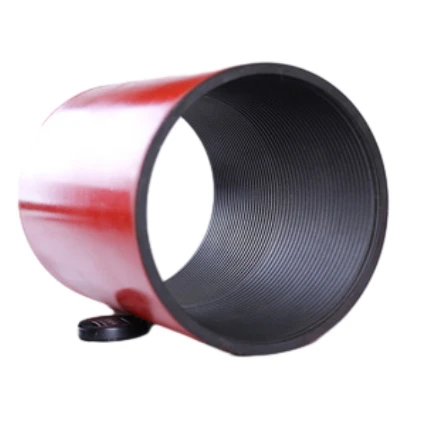

seating nipple in tubing

Seating nipples in tubing represent a crucial component in oil and gas operations, acting as a landing profile for various tools and serving as a fundamental part of well completion technology. The importance of effective seating nipples cannot be overstated, particularly when considering their role in maintaining production efficiency and ensuring the safety of oil extraction processes.

Trustworthiness in the context of seating nipples is validated by the consistent performance in the field. Real-world case studies highlight their ability to withstand environmental stresses and maintain seal integrity over extended periods, reinforcing their reliability. The reputation of manufacturers who demonstrate consistent quality controls and field support plays a significant role in earning client trust. A manufacturer’s commitment to ongoing research and development further solidifies their position as a trusted partner in oilfield operations. Finally, innovation in seating nipple technology focuses on enhancing durability and ease of use. The latest developments include self-sealing technologies and designs that allow for faster deployment and retrieval, minimizing operational downtime. Advanced materials such as high-performance alloys and composites are also being utilized to extend the lifecycle of these components under extreme conditions. In conclusion, the significance of seating nipples in tubing extends beyond their functional role; they embody the convergence of engineering excellence and operational reliability. Industry professionals looking to optimize their oil and gas extraction processes would do well to consider the experience, expertise, and trustworthiness associated with the right seating nipple products and services. With the continuous evolution of industry standards and technological innovations, the future of seating nipples appears to be one of sustained advancement, assuring their indispensable role in the energy sector.

Trustworthiness in the context of seating nipples is validated by the consistent performance in the field. Real-world case studies highlight their ability to withstand environmental stresses and maintain seal integrity over extended periods, reinforcing their reliability. The reputation of manufacturers who demonstrate consistent quality controls and field support plays a significant role in earning client trust. A manufacturer’s commitment to ongoing research and development further solidifies their position as a trusted partner in oilfield operations. Finally, innovation in seating nipple technology focuses on enhancing durability and ease of use. The latest developments include self-sealing technologies and designs that allow for faster deployment and retrieval, minimizing operational downtime. Advanced materials such as high-performance alloys and composites are also being utilized to extend the lifecycle of these components under extreme conditions. In conclusion, the significance of seating nipples in tubing extends beyond their functional role; they embody the convergence of engineering excellence and operational reliability. Industry professionals looking to optimize their oil and gas extraction processes would do well to consider the experience, expertise, and trustworthiness associated with the right seating nipple products and services. With the continuous evolution of industry standards and technological innovations, the future of seating nipples appears to be one of sustained advancement, assuring their indispensable role in the energy sector.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products