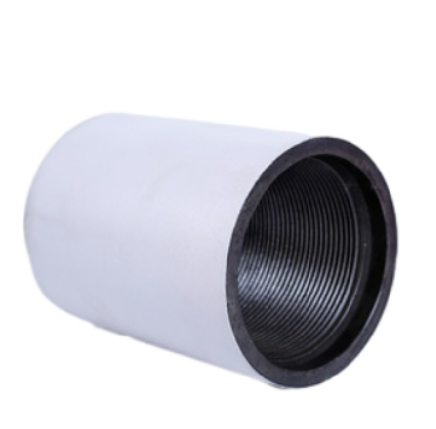

Tubing Coupling: The Small Connector with a Big Impact

In the oil and gas sector, a tubing coupling might be small in size, but its role is massive. Designed to securely join two sections of tubing, it ensures a leak-free and mechanically sound connection in high-pressure environments. Without reliable couplings, the integrity of the entire tubing string could be compromised, leading to operational inefficiencies or even costly well failures.

Built for Strength and Longevity

A steel pipe coupling is the go-to choice when durability is a priority. Manufactured from premium-grade carbon or alloy steel, these couplings are engineered to handle extreme wellbore conditions, including high torque, pressure surges, and corrosive fluids. Their robust design prevents joint loosening and guarantees consistent sealing performance over the lifespan of the tubing string. Steel pipe couplings are widely used not only in oil and gas wells but also in industrial piping systems where strength and reliability are paramount.

Precision-Machined for Perfect Fit

When it comes to maintaining flow integrity and safety, steel couplings for pipe are precision-machined to tight tolerances. This ensures that thread engagement is perfect, minimizing the risk of galling, leakage, or premature wear. In demanding environments, these couplings serve as the backbone of secure piping connections, resisting vibration, temperature fluctuations, and chemical attack. Their adaptability allows them to be used in diverse industries, from energy and petrochemical to marine and infrastructure projects.

The Corrosion-Resistant Choice

A stainless steel coupling offers all the mechanical advantages of steel while providing superior resistance to rust and chemical corrosion. This makes it ideal for operations in offshore platforms, sour gas fields, and any environment where moisture, chlorides, or corrosive fluids are present. The chromium content in stainless steel forms a passive oxide layer that protects the coupling from degradation, extending its service life and reducing maintenance costs. For operators prioritizing longevity in challenging conditions, stainless steel couplings deliver both strength and peace of mind.

Why Quality Couplings Matter in Well Performance

Couplings are more than just connectors—they are safety-critical components that directly affect production efficiency, environmental protection, and cost control. Choosing the right tubing coupling, steel pipe coupling, steel couplings for pipe, or stainless steel coupling means ensuring that every section of the tubing or pipeline works together seamlessly. High-quality couplings minimize downtime, prevent leaks, and safeguard both equipment and the environment, making them a non-negotiable investment for serious operators.

Tubing coupling FAQs

What is the difference between a tubing coupling and a pipe coupling?

A tubing coupling is specifically designed for oilfield tubing strings, while a pipe coupling is more general-purpose and used in various industrial piping systems.

Are stainless steel couplings stronger than carbon steel couplings?

Both offer high strength, but stainless steel couplings have the added benefit of corrosion resistance, making them better for harsh environments.

Can steel couplings be reused?

Yes, if they pass inspection for thread integrity, wear, and sealing surfaces, steel couplings can often be reused, though it depends on operational conditions.

Do couplings affect wellbore integrity?

Absolutely. Poor-quality or damaged couplings can lead to leaks, pressure loss, or structural failure in the tubing string.

When should stainless steel couplings be used?

They are best for offshore, sour service, or high-corrosion environments where long-term durability is essential.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025