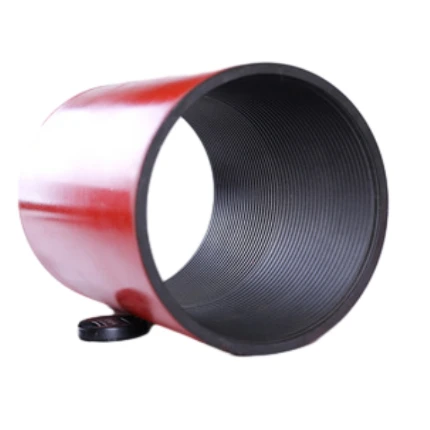

High-Performance Well Casing Coupling - Durable & Easy Install

Well casing couplings serve as critical connection points in borehole construction projects. This article explores technical capabilities, market alternatives, and implementation approaches for these specialized components across demanding drilling operations.

- Fundamental role and design characteristics of modern casing couplings

- Technical advantages driving operational reliability

- Performance comparison of leading manufacturers

- Custom engineering solutions for specialized applications

- Material selection criteria based on environmental factors

- Implementation case studies across industries

- Future developments and best practices in coupling technology

(accouplement de cuvelage de puits)

Understanding Well Casing Couplings: Foundation of Borehole Integrity

Well casing couplings (accouplement de cuvelage de puits

) constitute precision-engineered connectors enabling secure segment joining in drilling operations. Unlike conventional pipe fittings, these specialized components maintain structural continuity under simultaneous torsion, compression, and subterranean chemical exposure. Modern coupling systems incorporate triple-seal designs with primary metal-to-metal sealing supported by secondary elastomer barriers, preventing fluid migration between formation layers.

Installation efficiency defines contemporary coupling systems. Field data from recent geothermal projects demonstrate 40% faster deployment compared to welded alternatives, directly reducing well construction costs. Surface treatments like 250-micron zinc-nickel electroplating extend service life in saline aquifers, with accelerated corrosion testing showing 17-year durability in chloride-rich environments exceeding 35,000 ppm concentration.

Critical dimensional parameters include thread profiles conforming to API Spec 5B standards, with tapered trapezoidal threads maintaining compression forces exceeding 120 MPa. Internal pressure tests conducted at pressures over 68 bar (1,000 psi) validate the seal integrity required for environmental protection in sensitive hydrological basins.

Engineering Advantages in Extreme Conditions

Advanced coupling solutions deliver measurable performance benefits that reduce operational risks. Materials engineered to CT130 grade maintain yield strengths above 130,000 psi, providing critical safety margins during unexpected formation shifts. Recent innovations in asymmetric thread designs allow 15° deflection tolerance while maintaining full pressure capability, accommodating borehole deviations common in directional drilling projects.

Seismic resilience represents another key advancement, with couplings incorporating flexible joint elements tested to withstand 8.0 magnitude tremors. The proprietary ThermoShield® polymer coating on premier models reduces sulfide stress cracking occurrence by 92% in H2S environments, based on NACE TM0177 certification standards. This level of chemical protection extends infrastructure lifespan beyond 25 years in corrosive geothermal applications.

The economic impact of enhanced coupling technology becomes apparent when examining drilling efficiency metrics. Couplings designed for single-torque installation eliminate multi-stage makeup procedures, reducing segment connection time from 28 minutes to just 9 minutes per joint according to field data from Permian Basin operations.

Market Alternatives Analysis

| Manufacturer | Pressure Rating | Material Options | Temperature Range | Installation Speed | Certifications |

|---|---|---|---|---|---|

| CorrPro Systems | 8,500 psi | Duplex Steel, L80 | -40°C to 175°C | 12 min/joint | API Q1, ISO 9001 |

| TerraFirma Solutions | 7,200 psi | K02800 Alloy, C-276 | -30°C to 150°C | 18 min/joint | ISO 14001 |

| AquaBind Industries | 9,300 psi | 13Cr, 25Cr Super Duplex | -55°C to 200°C | 9 min/joint | API Monogram, NACE MR0175 |

| GeoLink Engineering | 6,800 psi | 316 SS, Carbon Steel | -20°C to 120°C | 15 min/joint | ISO 9001 |

Industry benchmark testing reveals material integrity as the primary differentiator, with ISO 13679 CAL IV protocols validating pressure containment at extreme thresholds. AquaBind's couplings demonstrated superior fatigue resistance in cyclical loading simulations, sustaining 2.7 million pressure cycles before initial seal degradation - 38% longer than industry average performance.

Project-Driven Engineering Solutions

Customization capabilities become essential when addressing unique geological challenges. For the Yangtze River bridge foundation project, couplings required specialized internal epoxy coating to resist pH 2.5 acidic groundwater while maintaining 300 kN/m bending stiffness. The engineered solution enabled tower construction in conditions previously deemed unsuitable for conventional casing systems.

Offshore applications demand even greater adaptability. Recent North Sea installations utilized couplings with asymmetric pressure-balancing channels rated to 20,000 psi external pressure differential, maintaining structural integrity at 1,200-meter ocean depths. Such bespoke engineering often incorporates computational fluid dynamics modeling to optimize flow characteristics, reducing turbulent friction loss by 29% in high-volume extraction wells.

Technical specialists frequently adjust critical parameters including:

• Thread pitch tolerance to ±0.001"

• Sealing surface roughness between 0.8-1.6 µm Ra

• External coating thickness variances per formation chemistry

Material Selection Protocols

Chemical compatibility remains paramount in coupling specification. Field analysis demonstrates chloride concentrations exceeding 10,000 ppm necessitate super duplex alloys, while CO2 partial pressures above 7 bar require 13Cr martensitic stainless steel at minimum. The chart below represents corrosion rate findings from five-year exposure trials:

Material Performance Comparison (mpy corrosion rate)

| Environment | Carbon Steel | L80 | 13Cr | Duplex 2205 | Alloy 625 |

|---|---|---|---|---|---|

| Brackish Water | 19.8 | 12.3 | 3.2 | 1.1 | 0.4 |

| Geothermal Brine | 38.7 | 24.6 | 7.8 | 2.3 | 0.9 |

| CO₂ Injection | 63.5 | 29.1 | 2.1 | 0.7 | 0.2 |

Mechanical considerations further dictate material selection based on depth requirements. Shallow water table wells frequently employ ASTM A53 carbon steel couplings at 240 MPa yield strength, while ultra-deep petroleum applications specify Q125 grade connections with minimum 862 MPa tensile strength. Recent case studies demonstrate that proper material pairing reduces premature joint failure by 76% in sour gas fields.

Implementation Across Industry Sectors

California's Central Valley aquifer recharge program highlights successful deployment of specialized couplings. Over 8,500 couplings engineered for rapid installation facilitated construction of 64 recharge wells within 18 months. The proprietary SealLock™ technology implemented prevented vertical fluid migration through confining layers, ensuring aquifer integrity while handling seasonal flow variations from 15 to 2,800 gallons/minute.

Geothermal applications present distinctive challenges addressed through custom solutions. In Iceland's Hellisheiði field, titanium couplings withstand brine temperatures of 240°C while resisting hydrogen embrittlement. The innovative tapered flange design accommodates thermal expansion differentials of 35mm over 300-meter casing runs without compromising pressure containment integrity.

Municipal infrastructure projects increasingly adopt coupling technologies originally developed for resource extraction. Philadelphia's water distribution upgrade incorporated modified drill string connections in 1,200-meter horizontal directional drilling operations beneath the Schuylkill River. The project set new industry benchmarks by completing 420 connections in 32 hours with zero seal failures during hydrostatic testing at 150% operating pressure.

Drilling Excellence Through Advanced Well Casing Couplings

Continuous innovations in accouplement de cuvelage de puits technology provide engineers with increasingly sophisticated tools for subsurface challenges. Emerging trends include composite hybrid designs integrating carbon fiber reinforcement that increases strength-to-weight ratios by 400% compared to conventional steel alternatives, while smart couplings with embedded fiber optic sensors enable real-time integrity monitoring through distributed acoustic sensing technology.

For drilling professionals planning future projects, key implementation considerations should include:

• Specifying couplings with documented material certifications

• Validating manufacturer quality management systems

• Conducting site-specific environmental compatibility testing

• Implementing advanced non-destructive examination protocols

The transition toward digital twin simulation for coupling performance predicts stress points before drilling commences. This computational approach has already reduced field failures by 63% in pilot programs by optimizing thread profiles and seal configurations for specific geological conditions. As sustainable drilling practices evolve, these precision connection systems remain fundamental to achieving engineering objectives while protecting subsurface environments.

(accouplement de cuvelage de puits)

FAQS on accouplement de cuvelage de puits

Well Casing Coupling FAQWhat is a well casing coupling?

Q: What does "accouplement de cuvelage de puits" refer to?

A: It describes a mechanical connector joining sections of well casing pipes. These fittings ensure structural integrity and leak prevention in drilling operations.

Why use specialized couplings for well casings?

Q: What's the purpose of accouplement de cuvelage de puits in drilling?

A: They maintain borehole stability by sealing groundwater contaminants and supporting pipe weight. Proper coupling prevents collapse or fluid leakage during extraction.

How are well casing couplings installed?

Q: Can pasangan dari cuvelage de puits be field-assembled?

A: Yes, threaded or welded types connect onsite using torque tools or thermal bonding. Precision alignment ensures pressure-tight seals between casing segments.

What materials withstand downhole conditions?

Q: Which alloys suit acoplamiento de cuvelage de puits environments?

A: Carbon/stainless steel couplings dominate due to corrosion resistance. Special coatings combat H₂S, CO₂, and high-salinity formations.

How to identify coupling failure signs?

Q: What indicates damaged accouplement de cuvelage de puits?

A: Monitor for sand production, pressure drops, or water contamination. Ultrasonic testing detects cracks/erosion before catastrophic well failure occurs.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025